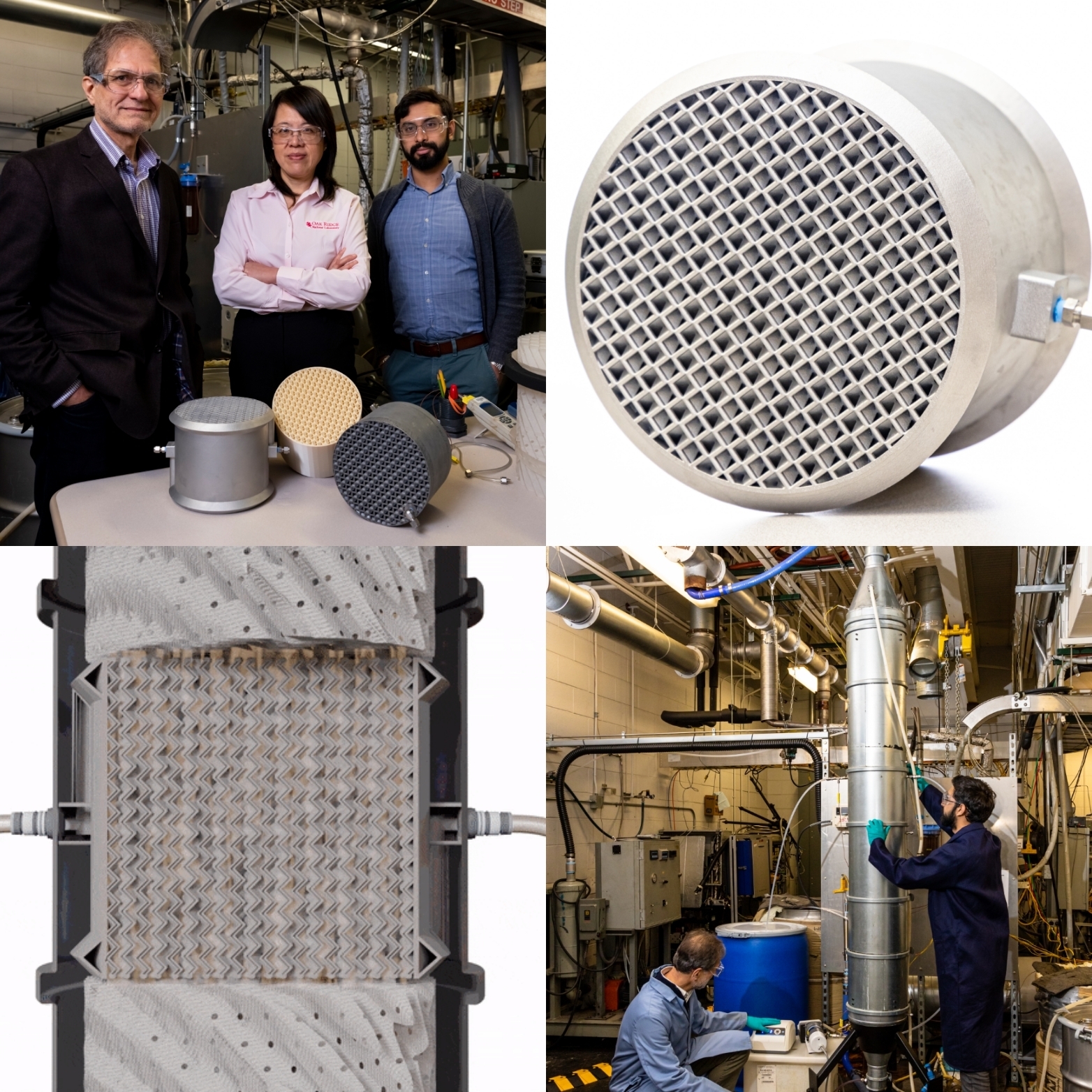

Oak Ridge National Laboratory (ORNL) engineers have 3D printed a unique aluminum device to enhance CO2 capture from fossil fuel plants and other industrial processes.

.

According to the scientists, the first-of-its-kind, low-cost aluminum device focuses on a key challenge in conventional absorption of carbon using solvents – a process known to produce heat and limit carbon capture’s overall efficiency. Absorption is one of the most commonly used and economical methods for capturing CO2. It places a flue-gas stream from smokestacks in contact with a solvent such as monoethanolamine (MEA) that reacts with the gas.

.

The team tested their novel circular device inside a 1-meter-tall by 8-inch-wide absorption column consisting of seven commercial stainless-steel packing elements. The ‘intensified’ device – which comes with a mass-exchanging contactor-driven heat exchanger – was installed in the top half of the column between the packing elements. 3D printing the device ensured that it could […]

Click here to view original web page at worldindustrialreporter.com

0 Comments