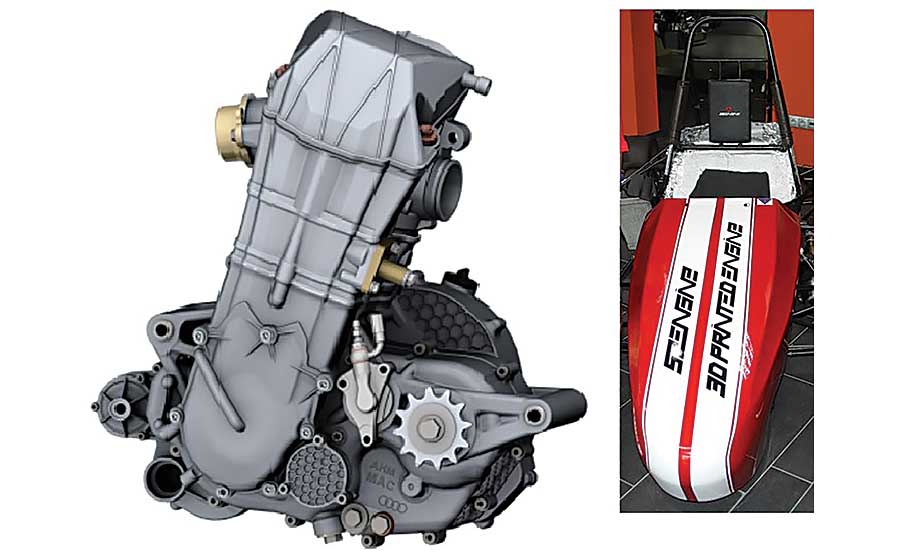

All the main components of the EVO6 engine are 3D printed using selective laser melting.

.

3D printing is a relatively quick process, creating a final prototype or a production-ready product with the technology can take months or even years. Hungarian college-student team SZEngine can attest to this, having produced the world’s first 3D-printed engine for use in a Formula Student racing car in 2018 after nearly two years of work.

.

The project began in 2016 when Zoltán Dudás, a 3D metal printing specialist at Audi Hungaria, based in Gyor, Hungary, was instructed to print a fully functioning engine using the SLM280 machine from SLM Solutions Group AG. Upon learning that SZEngine wanted to mill […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments