From capturing your breath to guiding biological cell movements, 3D printing of tiny, transparent conducting fibres could be used to make devices which can ‘smell, hear and touch’ – making it particularly useful for health monitoring, Internet of Things and biosensing applications.

.

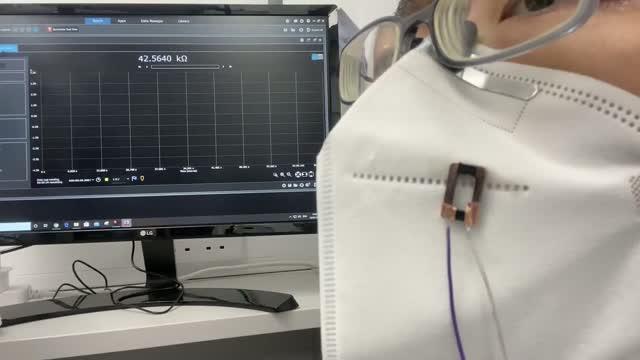

Researchers from the University of Cambridge used 3D printing, also known as additive manufacturing, techniques to make electronic fibres, each 100 times thinner than a human hair, creating sensors beyond the capabilities of conventional film-based devices. The fibre printing technique, reported in the journal Science Advances, can be used to make non-contact, wearable, portable respiratory sensors. These printed sensors are high-sensitivity, low-cost and can […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments