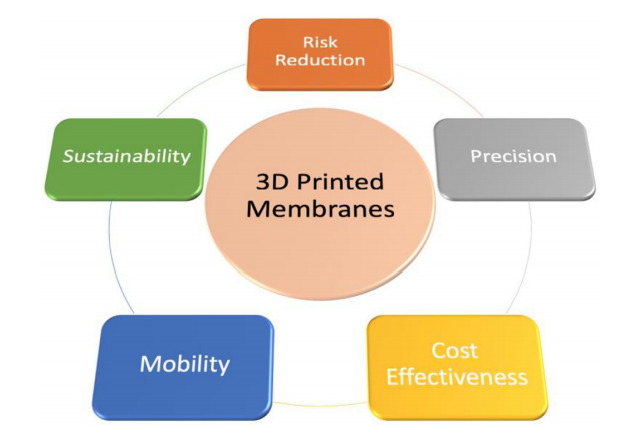

Researchers from the US and Korea are delving further into the technology of water purification, releasing their findings in ‘ Toward greener membranes with 3D printing technology .’ With the need for greener processes in many industries today, scientists around the world are investigating more energy-efficient techniques.

.

Water, and the critical nature of purification for sustaining human life, is no exception. The use of membranes continues to grow in popularity for the prevention of contamination, but as the authors point out, there are many drawbacks that still need to be solved—and improved fabrication is at the top of the list.

.

Currently, most membranes are created through techniques like electrospinning, interfacial polymerization, and other methods such as phase inversion—extremely popular for commercial production of membranes. “Most porous polymeric membranes are fabricated via non-solvent induced phase separation (NIPS) and thermally induced phase separation (TIPS) methods. For NIPS, the polymer solution is […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments