In the recently published ‘ Infill pattern and density effects on the tensile properties of 3D printed PLA material ,’ researchers from Indonesia delve further into the details of fabrication with polylactic acid (PLA) material, working with three different infill densities and patterns.

.

While both acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA) are commonly used in 3D printing, for this study the researchers focused on PLA—often chosen due to affordability, accessibility, and potential for producing innovative, lightweight prototypes and parts. Not only that, because of its plant-based nature, PLA is biodegradable and more environmentally friendly.

.

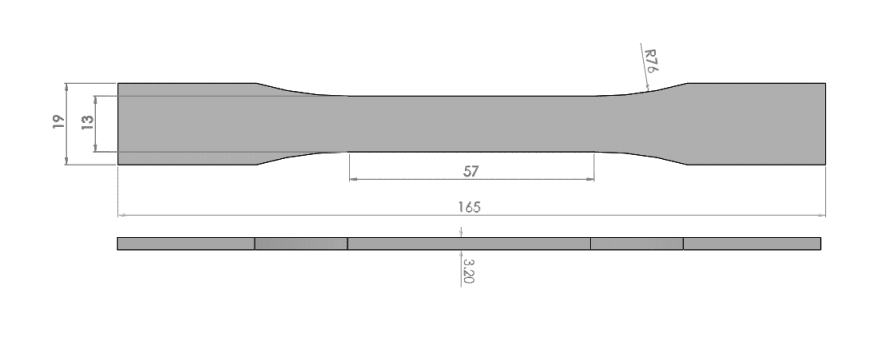

Mainly investigating infill density and infill pattern, the research team used tensile tests to reveal material properties, varying parameters to test properties such as tensile strength, yield strength, and ultimate strength. The following infill densities were chosen: 25 percent 50 percent 75 percent Three infill patterns were used: Grid Tri-hexagon Concentric Five samples […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments