If anything, 3D printing has been an inspiration for out-of-the-box thinking.

.

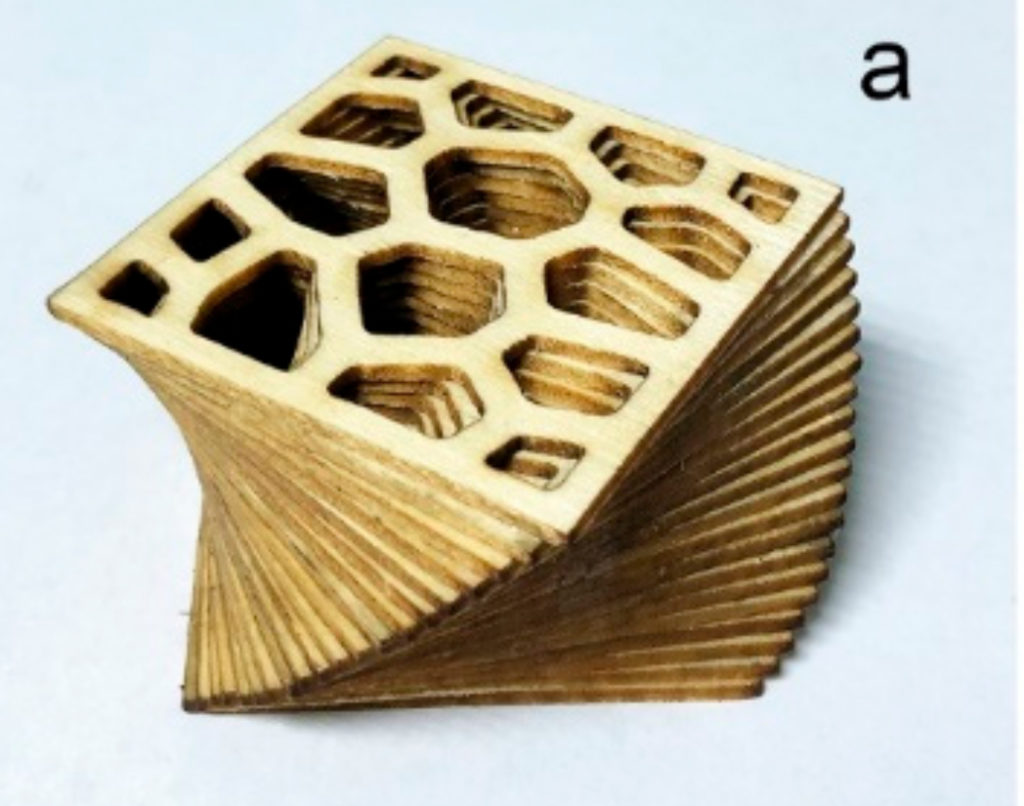

The plethora of additive technologies out there have become a jumping off point for an entirely new landscape of manufacturing processes. This includes a novel method for 3D printing large wooden structures, developed by researchers from Qilu University of Technology and the College of Material Science and Engineering, Northeast Forestry University , both in China. Authors of an article titled “ An Additive Manufacturing Method Using Large-Scale Wood Inspired by Laminated Object Manufacturing and Plywood Technology ” in the journal Polymers , Yubo Tao, Qing Yin and Peng Li, describe how laser-cut wood could be stacked in an additive manner to create wooden objects. They call the process laser-cut veneer lamination (LcVL) and it was inspired in large part by laminated object manufacturing (LOM), a method of 3D printing that has not yet found widespread use in the industry, but has several important, niche applications. LOM originated with a company called Helisys Inc., which laminated pieces of adhesive-coated material, such as plastic, together before cutting through the layers to produce a final object. While that firm’s iteration of the technology is now defunct, others have taken the concept […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments