The medical industry is changing quickly. While there have been major advances in the technological and biomedical engineering spaces, medical device manufacturers still need viable options for manufacturing devices and equipment both to patients and healthcare providers in an efficient, low-cost manner.

.

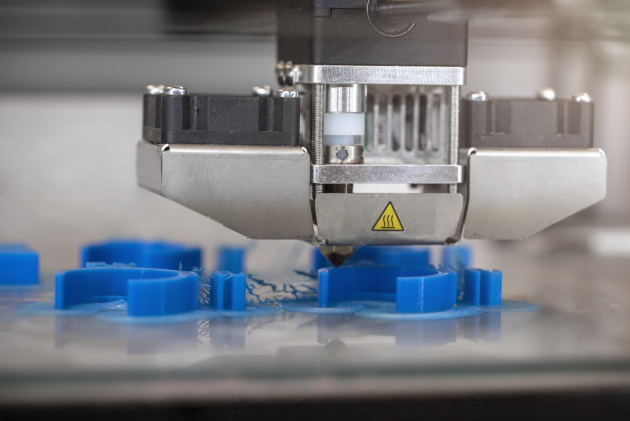

Moreover, the industry has an enormous need for customizable biocompatible and sterilizable components. While many device manufacturers still use traditional production methods, 3D printing is making it possible to create biocompatible and sterilizable components at a pace that is equally fast as inexpensive. Applications of 3D Printing in the Medical Field 3D printing has a number of novel applications that are making a big impact on the medical industry. These include: 3D Printed Prosthetics : Prosthetics need to be customized to meet the needs of each patient, making them both expensive and time-consuming to produce. Usually, the fitting process requires multiple castings and follow-up […]

Click here to view original web page at exclusive.multibriefs.com

0 Comments