Researchers at Lawrence Livermore National Laboratory (LLNL) used multimaterial 3D printing to develop tailored gradient refractive index glass optics , delivering a result that could enable the manufacture of improved military specialized eyewear and virtual reality goggles.

.

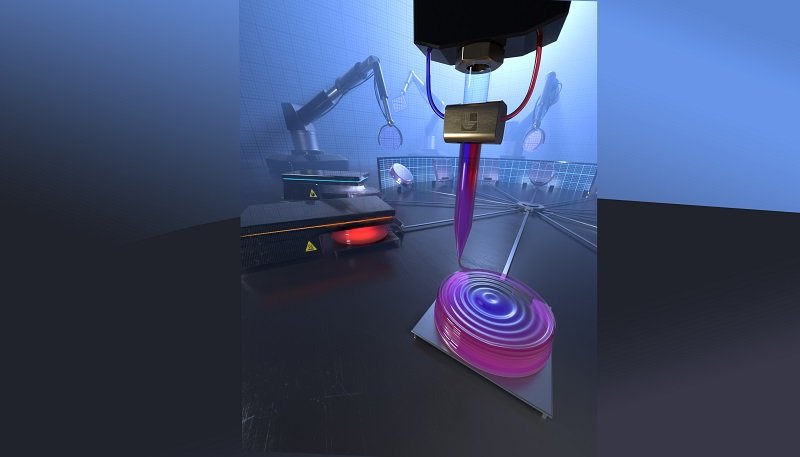

The technique has the potential to realize a variety of conventional and unconventional optical properties in a flat glass component, expanding the versatility in performance of environmentally stable glass materials. The team tailored the gradient in material compositions by controlling the ratio of two different glass-forming pastes or “inks” blended together inline using the direct ink writing method of 3D printing. After completing the composition-varying optical preform, the scientists densified it to glass. The material, they said, can be finished using conventional optical polishing methods. Artistic rendering of an aspirational future automated production process for custom GRIN optics, showing multimaterial 3D printing of a tailored composition […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments