As supply lines break and effects of novel coronavirus (COVID-19) become real, non-traditional fixes for problems have begun to appear.

.

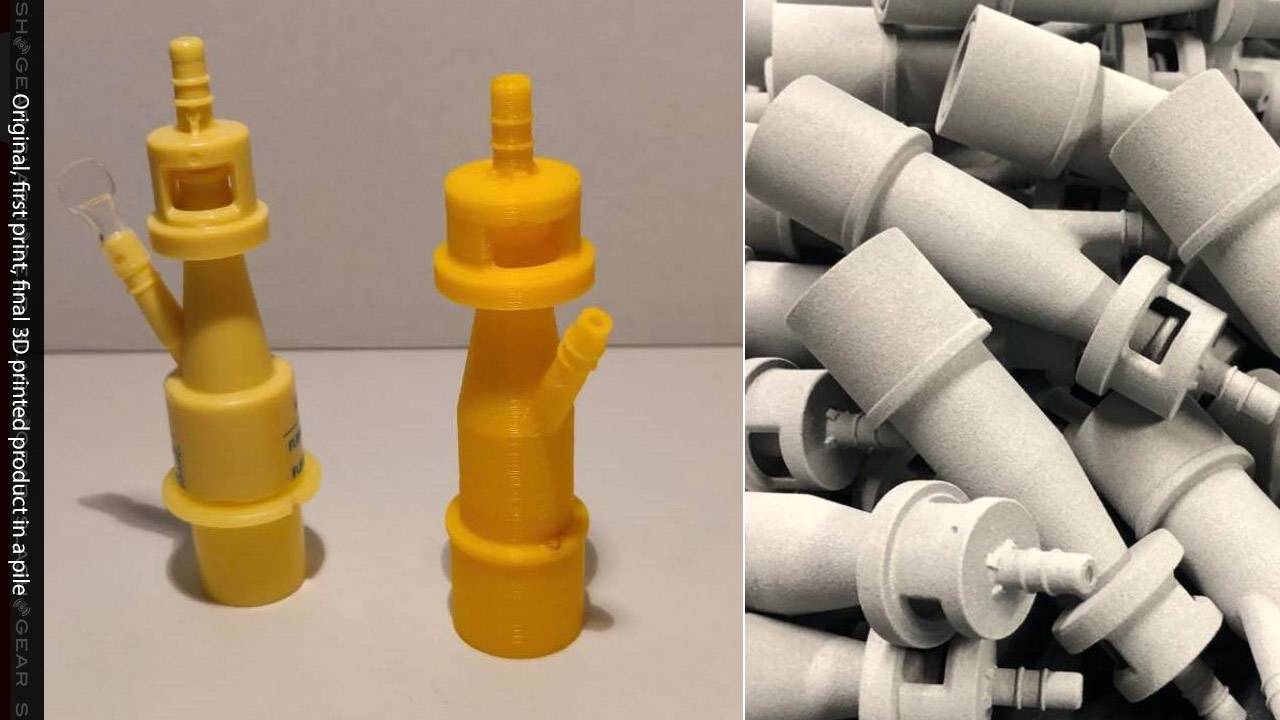

One Northern Italy hospital needed valves for a “reanimation device” on Friday of last week due to an extreme up-tick in cases thanks to COVID-19. The supplier of these parts had no way of getting fast replacements. A local 3D printing group stepped up and made the possibility of quick resupply a reality. Milan-based 3D printing group T

.

he FabLab was contacted on Friday by Nunzia Vallini, editor of the Giornale di Brescia, who informed the group that their services were needed. The founder of The FabLab, Massimo Temporelli, spoke with a number of FabLab locations and 3D printing companies in Milan and Brescia (location of the hospital itself). The company called Isinnova responded to the call. Isinnova founder and CEO Cristian Fracassi brought a 3D printer to the hospital. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments