Stereolithography (SLA) 3D Printers

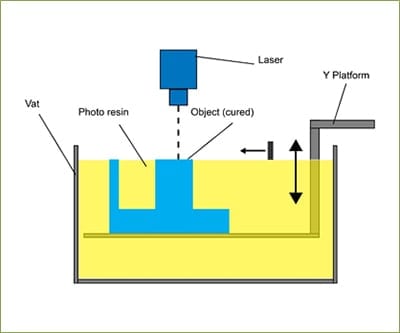

Stereolithography (SLA) was the first 3D printing technology. An SLA printer makes use of mirrors, with one positioned on the X-axis and another on the Y-axis. These mirrors rapidly aim a laser beam across the vat of resin, curing and solidifying a cross-section of the object inside this build area, building it up layer by layer.

Technology Overview

Vat Polymerisation

“Vat polymerisation uses a vat of liquid photopolymer resin, out of which the model is constructed layer by layer. An ultraviolet (UV) light is used to cure or harden the resin where required, whilst a platform moves the object being made downwards after each new layer is cured.

As the process uses liquid to form objects, there is no structural support from the material during the build phase., unlike powder based methods, where support is given from the unbound material. In this case, support structures will often need to be added. Resins are cured using a process of photo polymerisation (Gibson et al., 2010) or UV light, where the light is directed across the surface of the resin with the use of motor controlled mirrors (Grenda, 2009). Where the resin comes in contact with the light, it cures or hardens.”