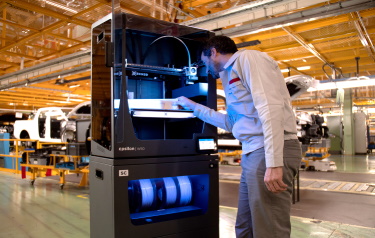

Bugatti is taking advantage of 3D printing to construct components for its series of low-volume models, what the company refers to as “one-off” cars.

.

The automaker first tested the waters a couple of years ago with a 3D-printed brake caliper made from titanium . The caliper ended up being 40 percent lighter than a normal cast caliper made from aluminum and was able to withstand temperatures as high as 2,000 degrees Fahrenheit.

.

Now, Bugatti is expanding the use of 3D printing for even more components for its hypercars. The automaker announced Wednesday that it is now also 3D printing the heat shields for exhaust systems on low-volume Chirons like the recently revealed Sport , Super Sport 300+ and Pur Sport , as well as the one-off cars like the La Voiture Noire , Divo and Centodieci . Each is unique, and like the brake caliper the new exhaust heat […]

Click here to view original web page at www.motorauthority.com

0 Comments