A grassroots effort, bubbling right here in Oregon, is helping solve one of the biggest problems our frontline heroes are facing: a rapidly dwindling stock of personal protective equipment (PPE).

.

Healthcare workers and makers joined up to help fill the need.

.

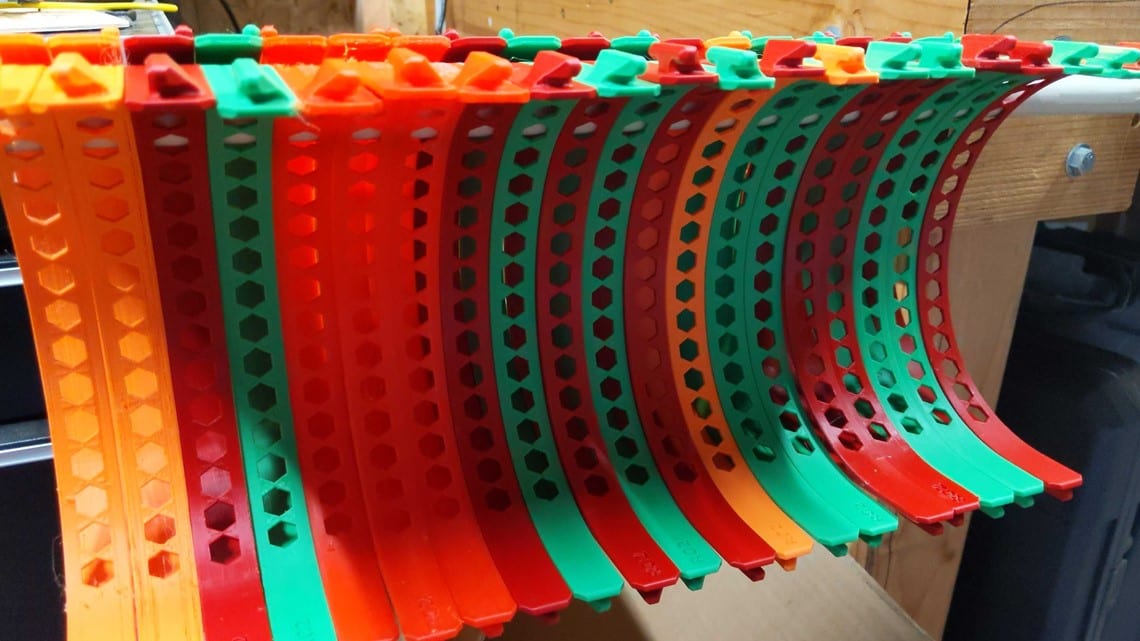

Brad Converse, an engineer by trade, coordinates and organizes the logistics out of his golf shop in downtown Grants Pass. He put together a team called “Covid Skunkworks” last Sunday after talking to a Southern Oregon hospital supply chain director. “Within less than 24 hours we had 35 local experts on the phone where we heard directly from the hospital what is the problem, what do you guys need, and then starting the very next day we were already delivering face shields. By now we have over 150 experts worldwide coordinating on this effort and we’ve already delivered face shield instructions to the world,” […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments