Brian Lovett, a product manager at an AdTech firm in Denver, Colorado, started 3D-printing quaint little knick-knacks–coffee coasters and orchids pots–for his home back in 2018. But when the coronavirus pandemic hit his city, two of Lovett’s close friends, both doctors in the emergency room of Denver Health , told him that their supplies of protective equipment would run dry within ten days.

.

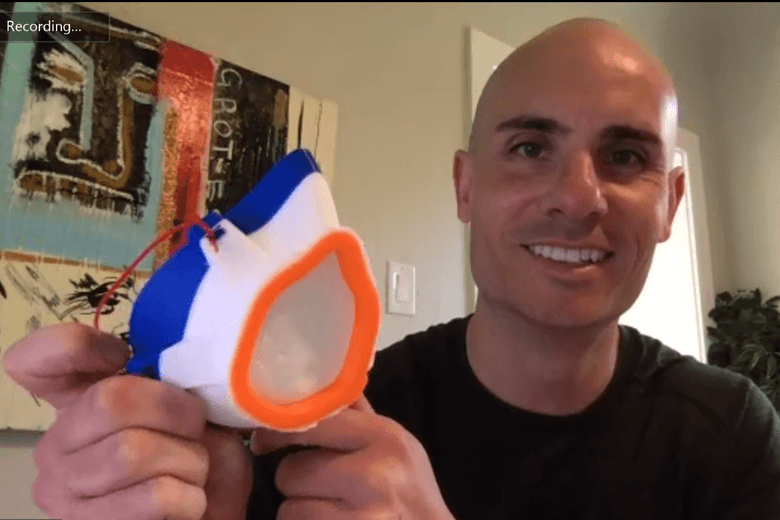

So, Lovett set his 3D printers on a different task: churning out protective face masks at a rate of 20 each day. Like a wartime Father Christmas, Lovett delivers the masks to his friends each morning, leaving them on their doorsteps in vacuum-sealed boxes. Lovett is one of thousands across America who have repurposed 3D printing machinery to produce medical equipment, such as face shields and face masks, for doctors on the front lines of the pandemic, bypassing the government and usually taking no profit in […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments