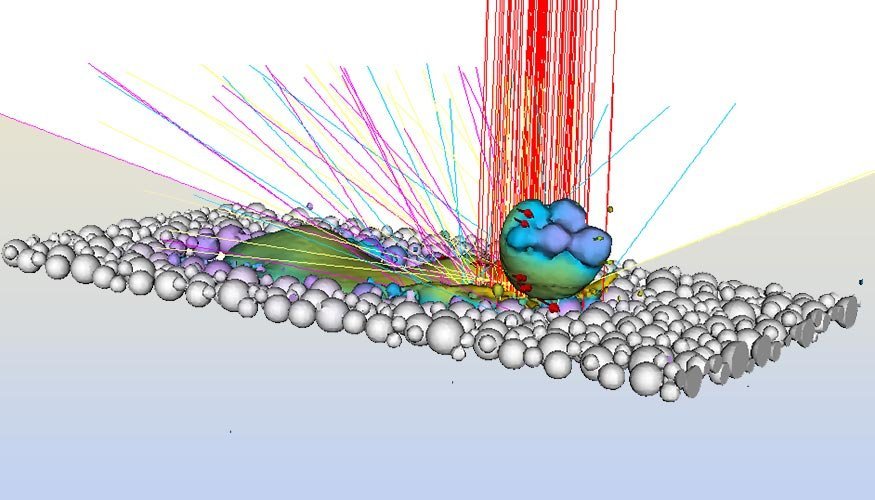

Combining high-fidelity computer simulations with ultra-high-speed X-ray imaging, researchers at Lawrence Livermore National Laboratory (LLNL) have discovered a strategy for reducing or even eliminating defects in parts built through a common, laser-based metal 3D-printing process.

.

In work published today (May 8, 2020) by the journal Science , a research team at LLNL, along with collaborators at the Air Force Research Laboratory, reveal previously unknown dynamics involved in the laser powder bed fusion additive manufacturing (LPBF-AM) process, which uses a laser beam to melt metal powder layer-by-layer to form 3D […]

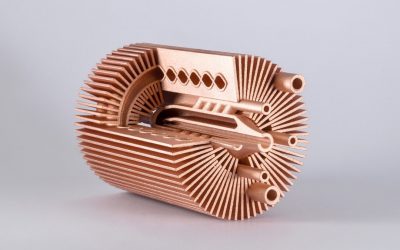

A New Tungsten Powder Compatible with Additive Manufacturing

Additive manufacturing with metal is gaining in popularity. This is shown, among other things, by the increasing...

0 Comments