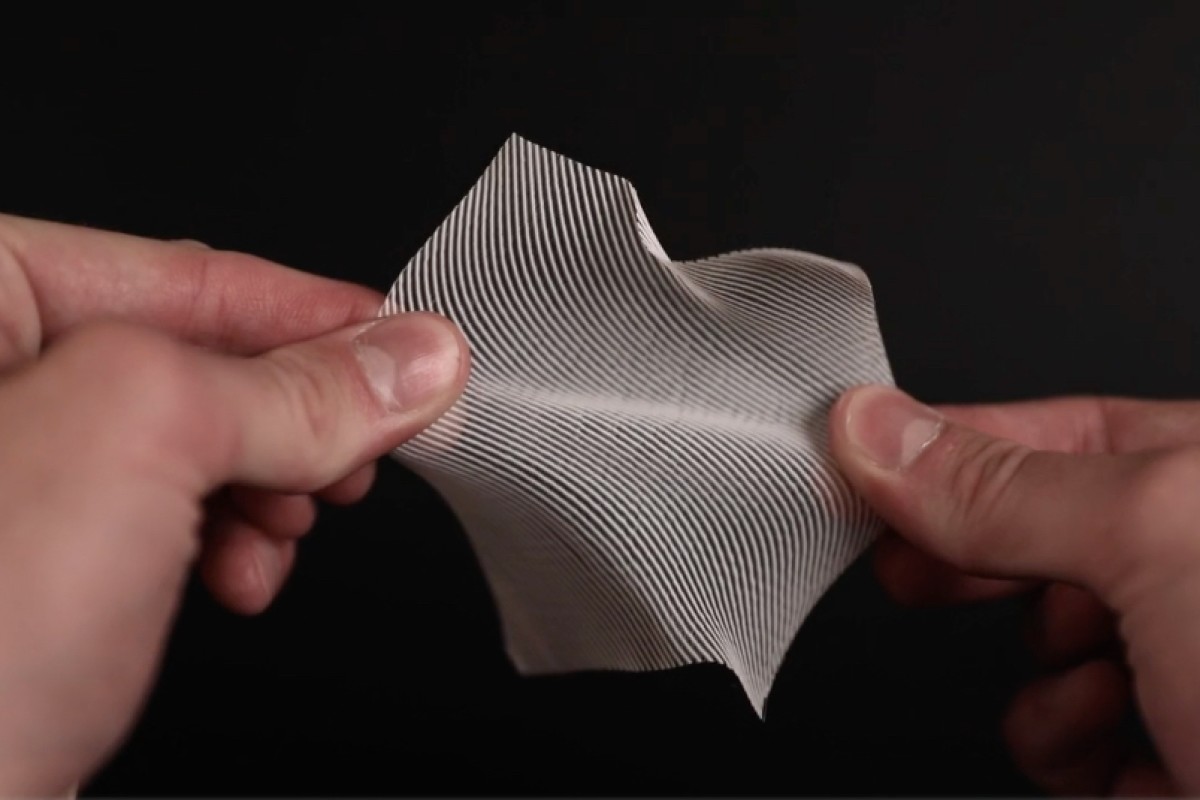

DefeXtiles can be 3D-printed out of various polymers, depending on the desired characteristics When a 3D printer leaves gaps in the plastic that it deposits, it’s usually thought of as an unwanted flaw. Now, however, the process has been harnessed to quickly and cheaply produce pliable polymer textiles.

.

Ordinarily, commonly used fused deposition modelling (FDM)-type printers create items by extruding successive layers of molten plastic. Once the layers of deposited plastic have cooled and fused together, they form a hardened solid object. Sometimes, though – due to a flaw in the printer or the programming – not enough plastic is extruded. This is known as under-extrusion, and it results in the finished product being full of small gaps.

.

MIT Media Lab grad student Jack Forman decided to put that error to use, creating a program that causes off-the-shelf, inexpensive FDM printers to under-extrude in a precise and controlled “glob-stretch” […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments