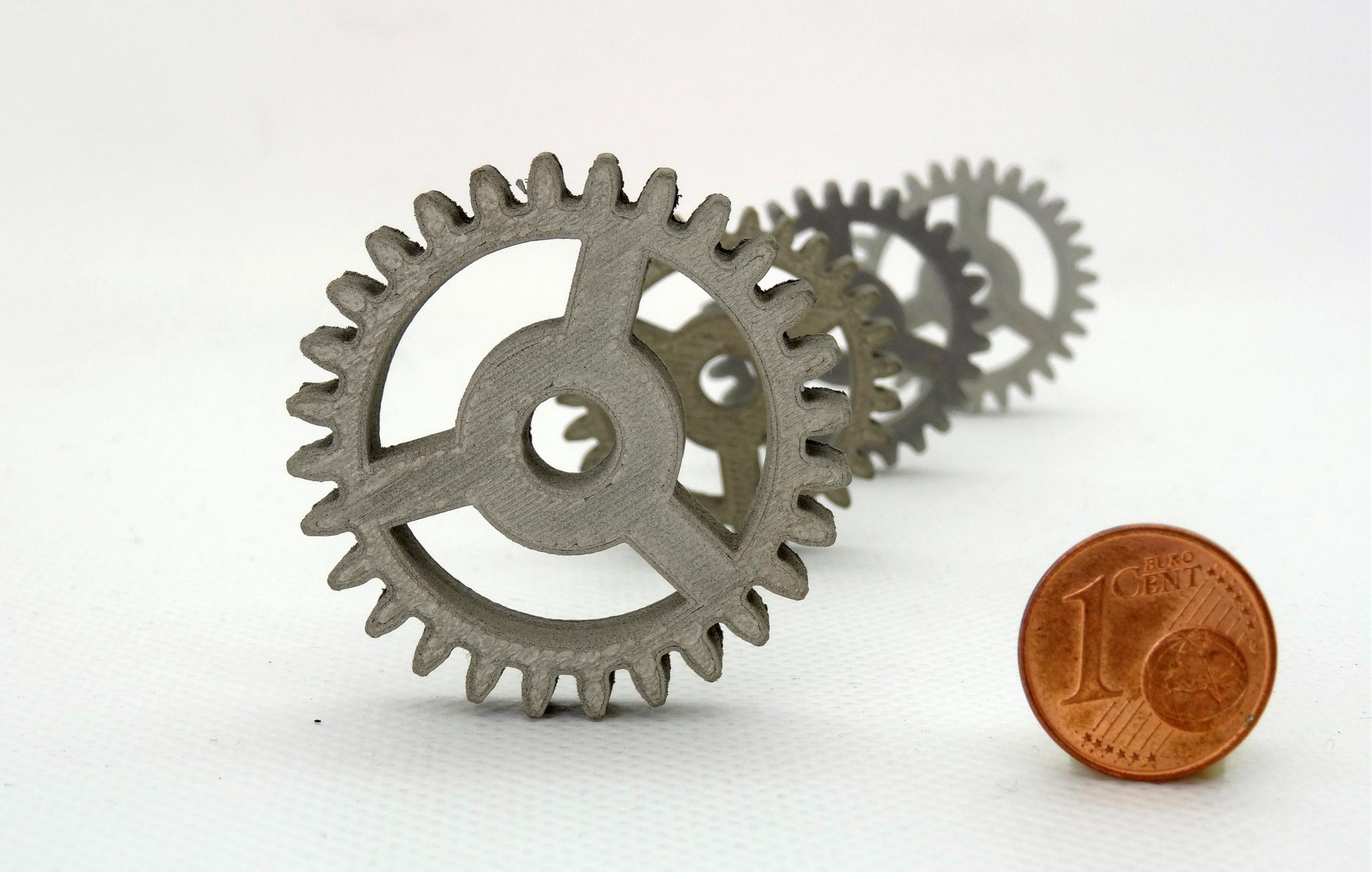

These spur gears – seen in the image above with a euro cent coin for scale – have been produced in stainless steel to a space standard of quality using nothing more than an off-the-shelf desktop 3D printer.

.

ESA-supported startup TIWARI Scientific Instruments in Germany has developed a technique allowing low cost 3D printing using a variety of metals and ceramics. Ordinarily producing precision parts in such high-performance materials would be costly in both time and money, but the company can instead shape them using standard 3D printing techniques. TIWARI’s ‘Fused Filament Fabrication’ (FFF) print process uses thermoplastic filaments that are embedded with particles of the metal or ceramic the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments