A group from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) developed an autonomous system that prints functional, custom-made devices and robots.

.

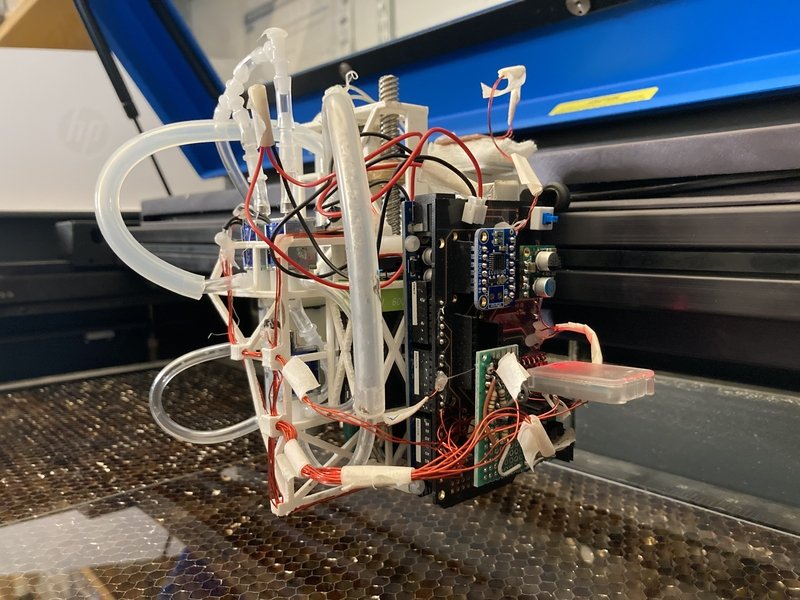

This single system, known as the LaserFactory uses a three-ingredient recipe that lets users create structural geometry, print traces, and assemble electronic components like sensors and actuators. Two parts work in harmony to make the Factory possible: a software toolkit that allows users to design custom devices, and a hardware platform that fabricates the devices.

.

CSAIL PhD student Martin Nisser says that this type of “one-stop shop” could be beneficial for product developers, makers, researchers, and educators looking to rapidly prototype things like wearables, robots, and printed electronics. “Making fabrication inexpensive, fast, and accessible to a layman remains a challenge,” says Nisser, lead author on a paper about LaserFactory that will appear in the ACM Conference on Human Factors in Computing Systems in May. “By leveraging widely available manufacturing platforms like 3D printers and laser cutters, LaserFactory is the first system that integrates these capabilities and automates the full pipeline for making functional devices in one system.” Inside LaserFactory Let’s say a user has aspirations to create their own drone. They’d first design their device by placing […]

Click here to view original web page at www.3dprintingmedia.network

0 Comments