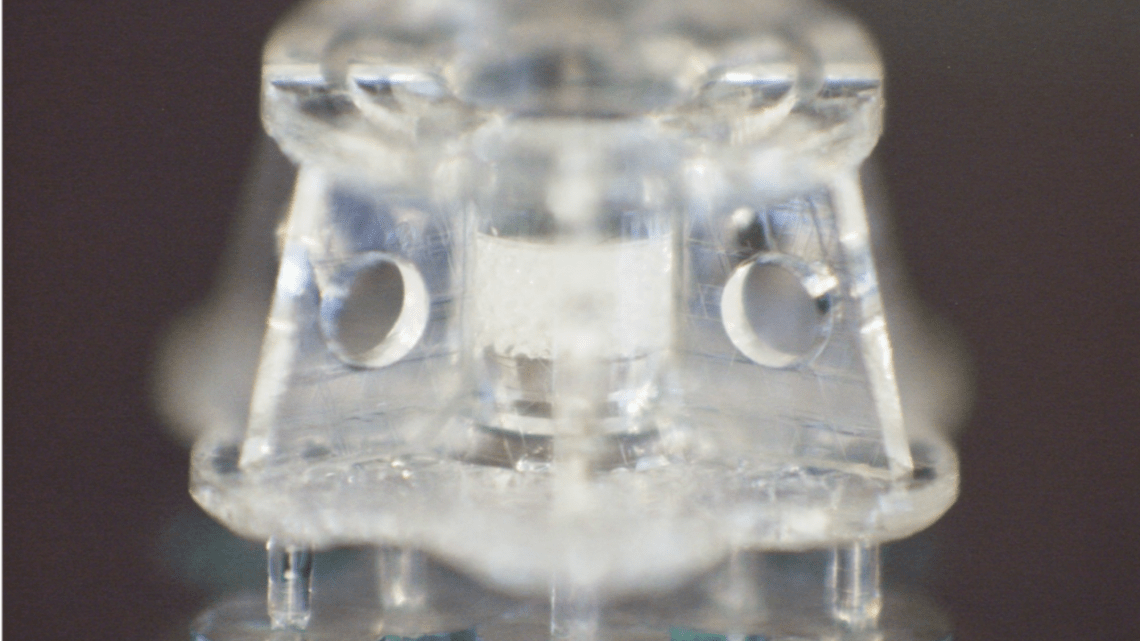

3D-printed gas diffusion layer for an electrochemical reactor, printed at the Cornell NanoScale Science and Technology Facility using two-photon polymerization.

.

Electrochemical reactors that can capture carbon dioxide and transform it into valuable products are a relatively new and promising technology for reducing greenhouse gas emissions. While many challenges exist to scaling up the technology, a new study highlights the benefits of using 3D printing, also known as additive manufacturing, to significantly improve cost, yield and efficiency. In electrochemical reactors like those that were studied, gaseous carbon dioxide travels through a porous gas diffusion layer for distribution to the catalyst, where it dissolves into a liquid electrolyte and converts to various products like fuels, lubricants and polymers.

.

Using additive manufacturing to rapidly prototype reactors with unique shapes and topologies, designs could be optimized for improved conversion rates, according to study co-author Sadaf Sobhani , assistant professor in Cornell University’s Sibley School of Mechanical and Aerospace Engineering. Members of Cornell’s Sobhani Lab. “Instead of focusing on engineering the catalyst, electrode or electrolyte, we focused on how the geometry – the distance between the electrodes or connections between compartments – influences system performance,” said Sobhani, who began the research as a postdoctoral […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments