Researchers are getting even more in-depth with the study of materials and 3D printing with metal in the recently published, ‘ Activated Carbon in the Third Dimension—3D Printing of a Tuned Porous Carbon .’

Seeking to create hierarchically structured porous carbons, the team of scientists from Technische Universität Darmstadt experimented with SLA 3D printing to create a new form of mechanically stable structures.

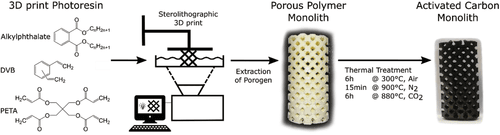

Schematic overview of the 3D printing process, starting from the liquid photoresin, then producing a porous polymer open cell structure (tetragonal unit cell) by stereolithographic 3D print and subsequent extraction of the porogen phase, finally yielding an activated carbon open cell structure upon a thermal treatment consisting of stabilization in air, pyrolysis in nitrogen and activation in CO2. Usually obtained in the form of powder, carbons may be classic black, activated, or nanomaterial. Often though, conductivity levels in these types of powder are low—causing ohmic losses […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments