In the recently published ‘ Microfluidics as a Platform for the Analysis of 3D Printing Problems ,’ by Rui Mendes, Paola Fanzio, Laura Campo-Deaño, and Francisco J. Galindo-Rosales, the authors explore FFF 3D printing and the inherent challenges, with a focus on extrusion flow problems and microfluidics as a way to study and solve the issues, along with other problems like misalignment, complete failure of parts, back-flow, and blockage of nozzles overall.

.

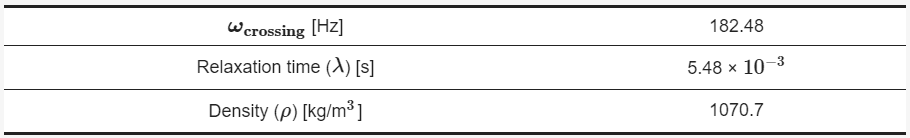

Printing conditions were defined regarding the Deborah number (De), the Reynolds number (Re) and the Elasticity number (El), with the cross-section of each nozzle’s structure copied in a planar microfluidic chip. The researchers constructed these replicated cross-sections with polydimethylsiloxane, and a range of fluids meant to represent a similar elasticity number to polycarbonate.

.

Design of the nozzle involved a variety of four different scale ratios, with each microchannel possessing an inlet and outlet port. “Between the inlet […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments