In the recently published, ‘ Increasing the Writing Resolution for Electro-hydrodynamic 3D-Printing: by Active Steering of e-jet ,’ author Henrik Dan Bergman explores fabrication techniques in the microscopic realm for his thesis in Microsystems Technology at Sweden’s Uppsala University.

.

Electrohydrodynamic 3D-printing is a central focus, and especially due to its ability to print with thermoplastics. Historically, however, there have been challenges with writing resolution due to the rigors of the production process.

.

Bergman considers whether it would be possible to improve writing resolution with a closed-loop feedback system.

.

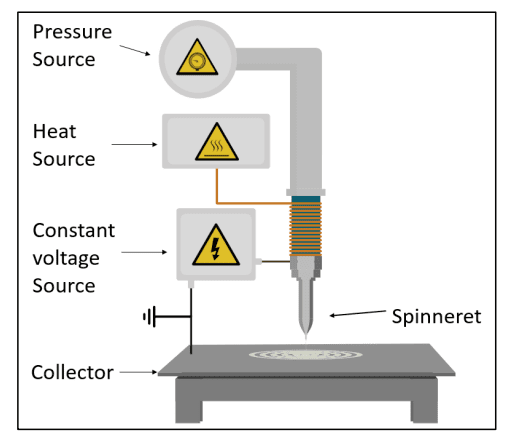

Crucial components for melt EHD printing. Reproduced from [7]. Despite the amount of study devoted to EHDP, low production rate is a problem too. For this research, Bergman noted a production rate of 1mm3 in 20 minutes at the experimental lab built by Uppsala University for developing EHD 3Dprinting. The ongoing focus was in creating a closed feedback system to […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments