In the recently published ‘ Vibration Analysis of Cantilever Shaped 3D Printers ,’ researchers A. Srivastava, C. Gautam, N. Bhan, and Ram Dayal discuss how to improve 3D printing hardware further, as users’ needs continue to evolve. Focusing on the range of technology available—and varied accessibility and affordability—the authors endeavor to refine capabilities further using vibration techniques, expecting their study to affect the RepRap open-source community in a positive way.

.

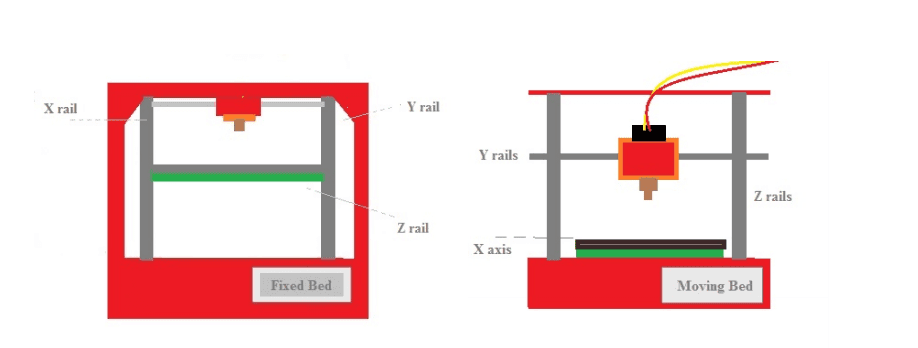

Much 3D printing research has been centered around FDM 3D printing and ways to improve both mechanical and surface properties. In this study, the researchers are also exploring quality in performance due to better mechanical properties, but also how vibration during 3D printing can cause defects. While the 3D printer employed may seem sturdy and capable, stability may be an issue during the actual process. As layers are being fabricated, vibrations may affect surface quality significantly. The researchers recognize […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments