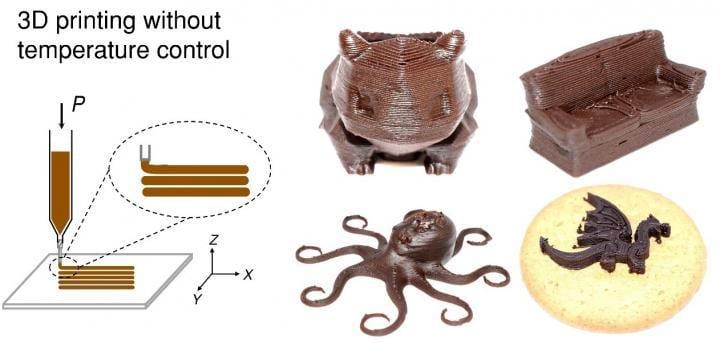

SUTD’s new approach to the 3D printing of chocolate using cold extrusion instead of conventional hot-melt extrusion method eliminates the need for stringent temperature controls, offering wider potential for 3D printing temperature-sensitive food

.

SUTD Researchers from the Singapore University of Technology and Design (SUTD) have pioneered a novel approach to 3D print chocolate-based products at room temperature by cold extrusion. The hot-melt extrusion method is widely used in 3D printed chocolates where the chocolate is required to be between the temperatures of 31°C to 36°C so that it can be melted and dispensed accordingly.

.

While this method has its advantages in simplicity and accessibility, the narrow range of operating temperature can be highly restrictive and inflexible. Conversely, cold extrusion does not require the manipulation of temperature as it depends solely on the rheology of printing ink that is added to chocolate at the operating […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments