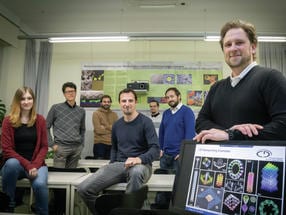

A team from Graz University of Technology succeeded in using the FEBID method to produce complex 3D-printed nano-components for the first time without additional support structures.

.

In the nanometer range, complex, free-standing 3D architectures are very difficult to produce in a single step due to the required precision. In the Christian Doppler Laboratory for Direct Write Fabrication of 3D Nano-Probes, scientists at Graz University of Technology are therefore devoting themselves to the fundamentals of 3D Nanoprinting to push its possibilities beyond current limitations.

.

For that, the research group uses the technology Focused Electron Beam Induced Deposition (FEBID), which is already used successfully in the production of complex but often flat nanostructures. More efficiency and more possibilities The CD lab research team has advanced the technology in such a way, that even complex three-dimensional nanostructures can be produced in a highly controlled and predictable way. In addition to the production […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments