The technology continues to evolve, but 3D printing is still mostly used for creating prototypes or parts that won’t have to endure tremendous stresses or rigorous wear and tear. That might not always be the case, however, as researchers at Rice University found a way to 3D print complex patterns resulting in plastic objects that are almost as hard and durable as diamond.

.

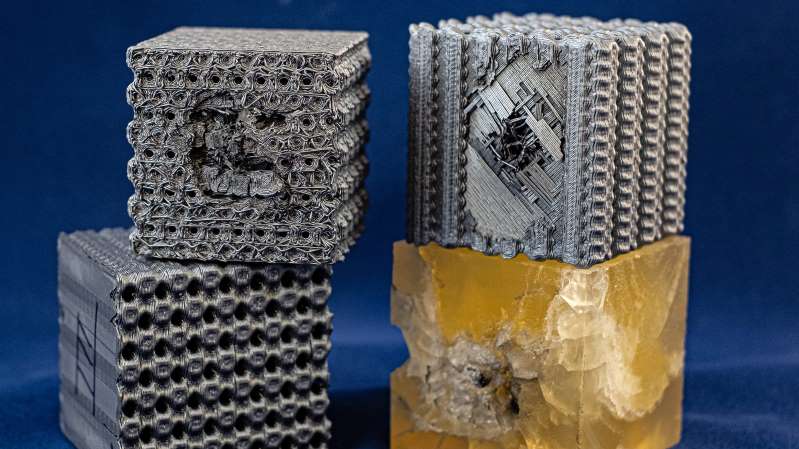

The complex crisscrossing and zig-zagging patterns that are used to build up the structures of these polymer cubes are far from random; they’re strategically calculated and engineered to give these objects their incredible strength, but can be tweaked and tuned to exhibit other amazing properties as well.

.

The patterns are based on tubulanes, which are theoretical microscopic structures made of crosslinked carbon nanotubes that were predicted to have remarkable properties in 1993 by chemist Ray Baughman and physicist Douglas Galvão. […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments