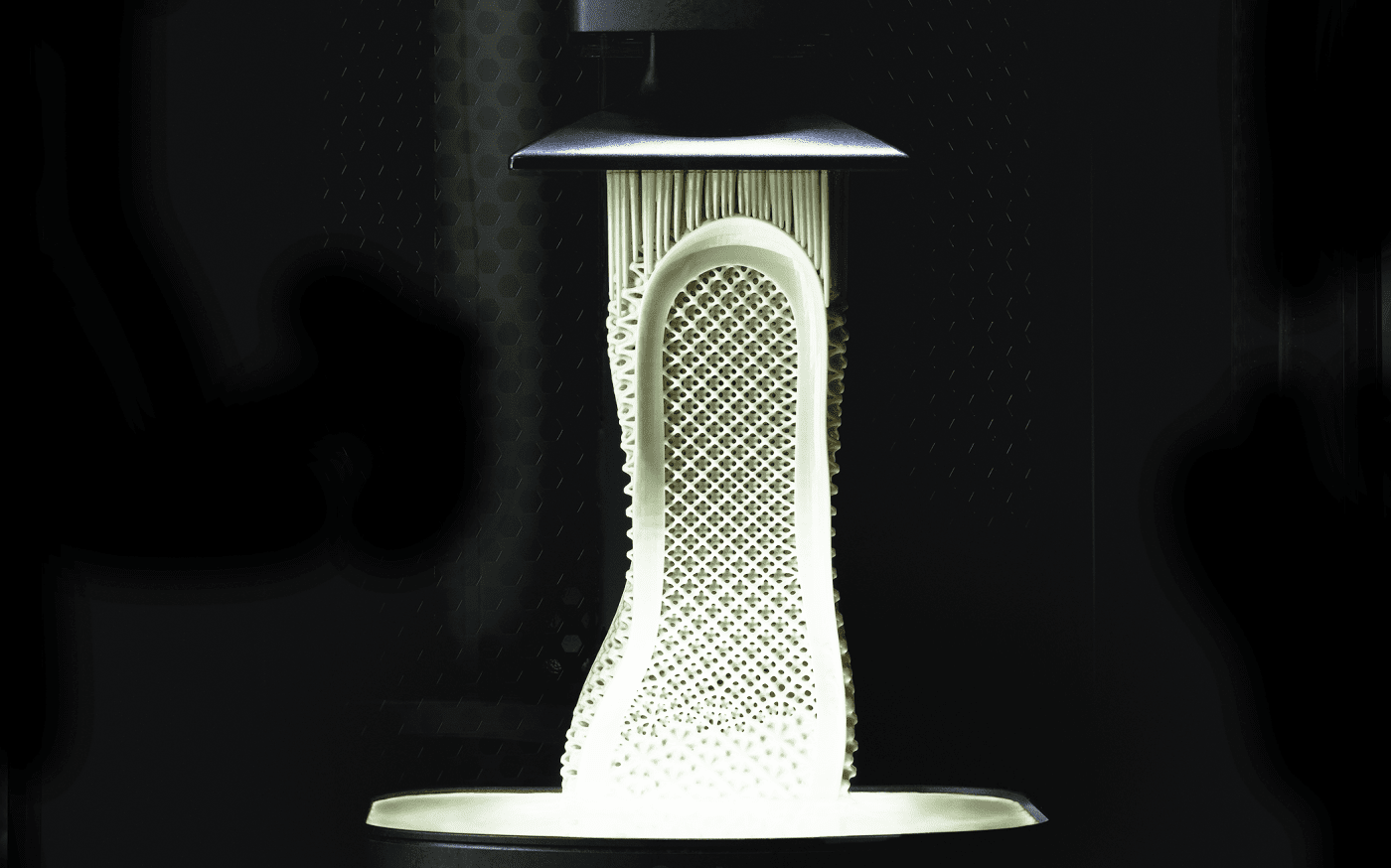

After disrupting product design and prototyping, 3D printing is changing the end-components that make shoes feel and perform even better.

.

For decades, insole and midsole manufacturers have been using the same foam as a baseline for innovation. Today, advances in 3D printing have produced a new alternative material, created to improve performance and design flexibility at a cheaper cost.

.

While footwear manufacturing is one of many industries now readily using 3D printing, the requirements are unique. Unlike with cars, for instance, the production time for shoes is usually a matter of months rather than years; as a result, designers need to innovate quickly to satisfy trend-conscious consumers. “I’ve witnessed a dramatically faster innovation cycle,” said Fabian Krauss, North American global business development manager at technology company EOS . “[Footwear] is less regulated, so there are not nearly […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments