A team of scientists from the Max Planck Institute for Intelligent Systems (MPI-IS) have developed a system with which they can fabricate miniature robots building block by building block, which function exactly as required.

.

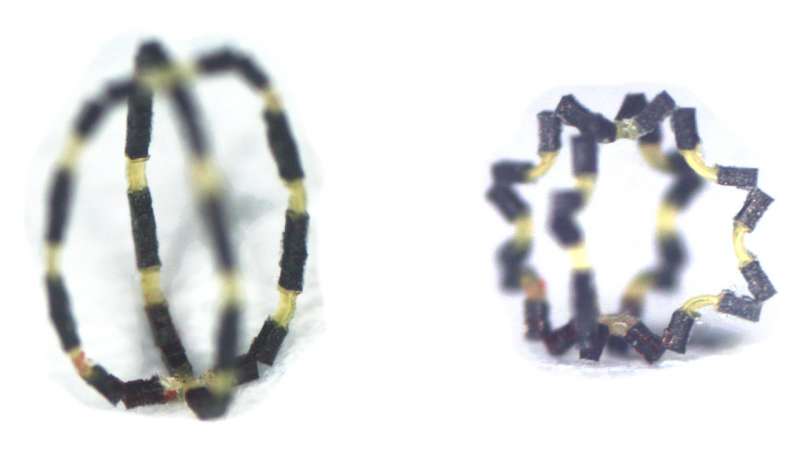

As one would do with a Lego system, the scientists can randomly combine individual components. The building blocks or voxels—which could be described as 3D pixels—are made of different materials: from basic matrix materials that hold up the construction to magnetic components enabling the control of the soft machine. “You can put the individual soft parts together in any way you wish, with no limitations on what you can achieve. In this way, each robot has an individual magnetisation profile,” says Jiachen Zhang. Together with Ziyu Ren and Wenqi Hu he is first author of the paper entitled “Voxelated three-dimensional miniature magnetic soft machines via multimaterial heterogeneous assembly.” The paper was published in Science Robotics on April 28, 2021. The project is the result of many previous projects conducted in the Physical Intelligence Department at MPI-IS. For many years, scientists there have been working on magnetically controlled robots for wireless medical […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments