While we’re big believers in 3D printing here at Hackaday, there’s no denying that some things just aren’t meant to be printed. For example, most of us would agree that it’s not the first choice for making rims for a passenger car. We imagine that [Jón Schone] from Proper Printing probably feels the same way, but that didn’t stop him from trying to do it anyway.

.

A couple of months ago [Jón] got a test subject in the form of an older Mercedes with 19-inch rims. The first two challenges are bed size and warping, so he modified a Creality CR10 S5 with a heated chamber capable of reaching 70 °C to reduce warping with the ABS filament he intended to use. Another challenge is the amount of filament required for the print, especially since [Jón] wasn’t keen on babysitting the machine to replace the spool every so often. His attempt at building a filament joiner ultimately didn’t work out , so in the end he simply sourced the filament in bulk size rolls. Bolts hold the two halves of the rim together. Eventually [Jón] managed to print a complete rim in two halves, bolted together around its […]

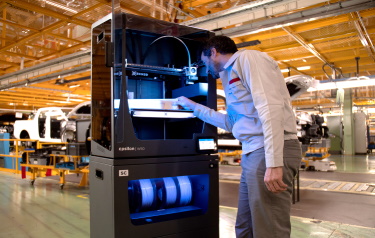

Nissan accelerates assembly line with 3D printing solution

Having successfully integrated 3D printing into its production process in its Barcelona factory, Nissan now has the...

0 Comments