The Army’s advanced manufacturing push intends to cut production timelines and costs throughout the lifecycle of systems, said an Army acquisition officer.

.

“Can you imagine how great it would be if we could just not have any parts in the logistics system, only raw materials, and we would just print the part at the point of need, right?” asked Maj. Gen. David Bassett, program executive officer for Command, Control, and Communications – Tactical, or C3T, during a panel discussion Wednesday.

.

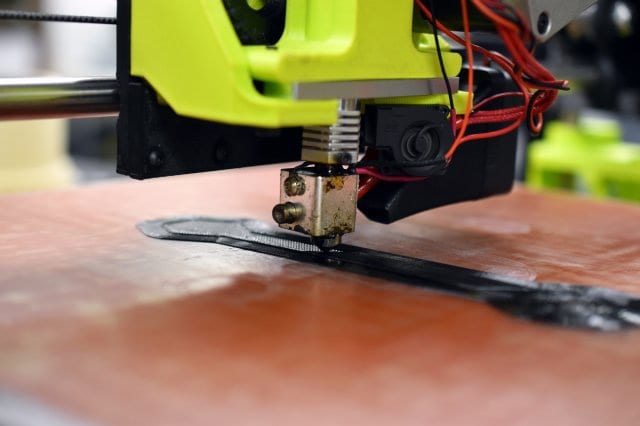

That vision has become synonymous with advanced manufacturing, he said during the Association of the U.S. Army’s “Hot Topic” forum on Acquisition and Contracting. Advanced manufacturing forges innovative technologies to “create new, or improved products or processes,” said Paul Mehney, C3T public communications director. One technique, additive manufacturing, incorporates 3D printing, robotics, artificial intelligence and composite materials. But according to Bassett, that’s just a fraction of […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments