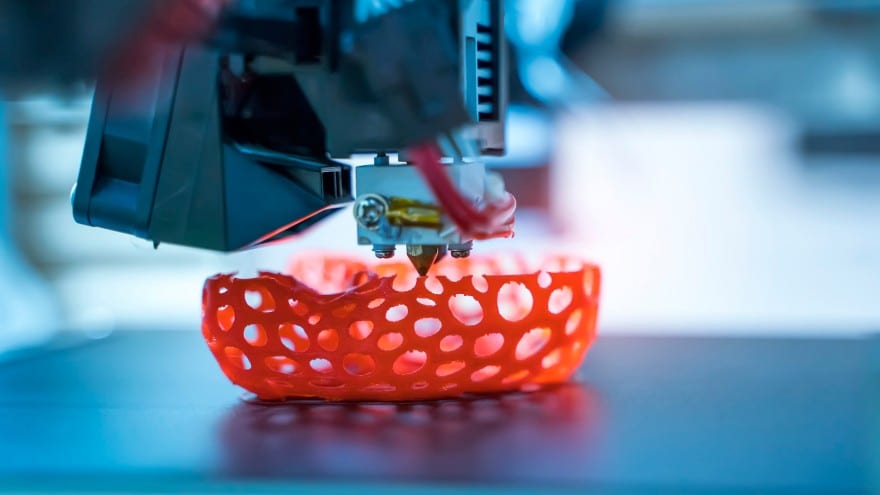

Researchers for the University of Auckland say they’ve developed a way to 3D print “living” plastic, calling it a world-first and a potential game-changer.

.

The resin is able to change its properties after it’s been produced – able to ‘self-repair’ when damaged, and ‘grow’ in size and mass. Researcher Kyle Engel, an honours student, says it could be used to develop shoes that grow with the wearer. Its ‘self-repairing’ properties could reduce plastic waste and improve recycling opportunities for items made with the material.

.

“If 3D printing, often called additive manufacturing, is the new frontier of the fourth industrial revolution, this new technique is at the forefront of that frontier,” research supervisor Jianyong Jin says. Because the plastic isn’t cured like normal 3D-prints with UV lights, it may also be suitable for new medical implants and devices where it’s not safe to use UV lights, the researchers say.

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments