3D printing has proven itself time and time again as a leading technology for making short runs of specialty components, hence its widespread use in aerospace. Mirroring developments in the aerospace sector is the use of additive manufacturing (AM) in luxury and autosports vehicles.

.

Bugatti has deployed the technology once again to 3D print titanium tailpipe trim covers for the Chiron Pur Sport and Chiron Super Sport 300+.

.

The trim cover measures a substantial 22 cm long by 48 cm wide and 13 cm tall while weighing only 1.85 kg, including the grill and bracket. By 3D printing the component using laser powder bed fusion, Bugatti was able to reduce the weight of the part by 1.2 kg. Design optimization included a lattice structure and filigree struts. At its thinnest points, the wall thickness of the part […]

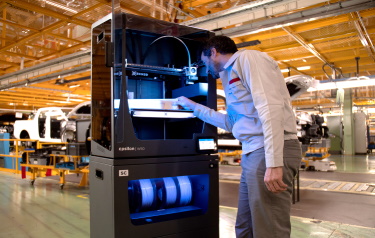

Nissan accelerates assembly line with 3D printing solution

Having successfully integrated 3D printing into its production process in its Barcelona factory, Nissan now has the...

0 Comments