A TEAM of innovative engineers is transforming the way vehicles are developed by PRINTING car parts.

.

CUPRA, which is the performance arm of SEAT, is using state-of-the-art multi-jet fusion technology to fashion parts in a fast and efficient way. CUPRA, which is the performance arm of SEAT, is using state-of-the-art multi-jet fusion technology to fashion parts in a fast and efficient way

.

For its new Leon Competición model, they have 3D printed the racer’s door mirror, air intakes and cooling intakes. The process of printing a mirror can take around 20 hours, but as they can print six at a time it gives the team the ability to create different designs simultaneously. This way they can quickly test the varying prototypes in a wind tunnel to find out which is best for aerodynamics. When taken to this controlled environment, the printed parts are fitted to the car and face […]

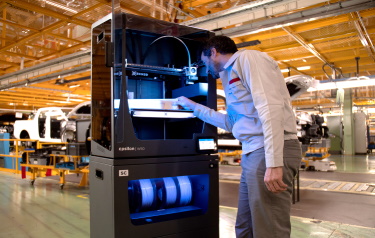

Nissan accelerates assembly line with 3D printing solution

Having successfully integrated 3D printing into its production process in its Barcelona factory, Nissan now has the...

0 Comments