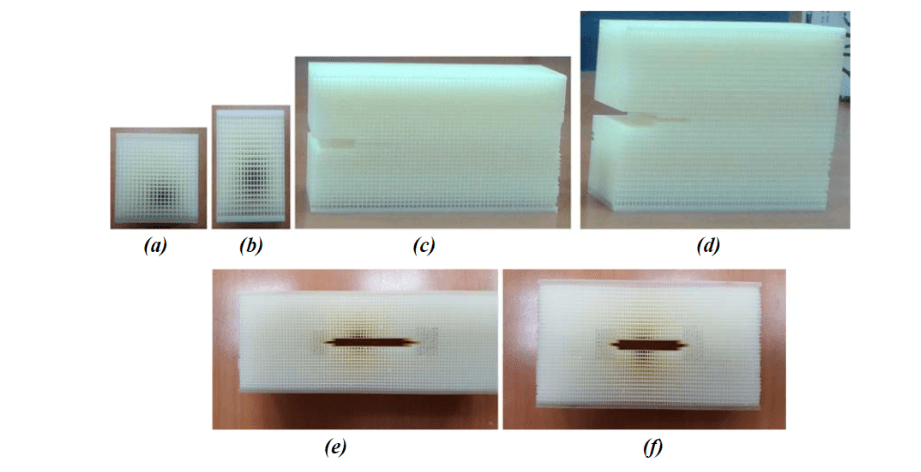

Israeli researchers Lihi Shenhav and Dov Sherman delve into testing 3D printed cell structures, outlining their findings in the recently published ‘ Fracture of 3D printed brittle open-cell structures under compression .’

.

Helpful in many applications due to volume, surface area, and weight, cellular materials are used in critical parts like fuel cells, catalysts, heat exchanges, and more; however, as tissue engineering continues to progress, they are also used in bio-inspired structures. ‘Anticrack’ is a term coined regarding crack propagation—like both biological and earth crust phenomena. While full bulk materials may exhibit crack propagation from tensile stress, porous material cracks may occur during compression causing issues like bone fractures, building collapses, avalanches, and more. There has been very little research performed regarding crack propagation under compression, however, leaving the authors motivated to study more about porous materials and why they break under duress.

.

The researchers tested samples for the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments