Researchers delve further into the relationship between technology, fabrication, and performance in ‘ On the Impact of the Fabrication Method on the Performance of 3D Printed Mixers ,’ examining how unibody lab-on-a-chip devices perform, depending on whether they are printed via polyjet, stereolithography (SLA), and FDM (FFF) platforms.

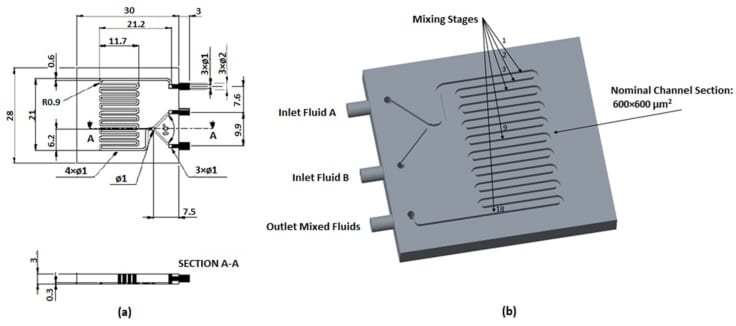

LOC devices, usually created (as the name would infer) in science labs, offer greater efficiency to numerous applications, including: Chemical Biological DNA and protein analysis Food safety control Drug development Computer-assisted design (CAD) drawing of the designed micro-mixer with dimensions in mm; (b) 3D model of unibody passive micro-mixer. Previously, such devices offered specialized, beneficial services, but were also high-maintenance due to the need for skilled operators and expense.

3D printing has brought substantial advantages to the manufacturing of LOC systems and devices, however, with all the classic benefits—from the ease in design and production to the ability to create more […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments