From Star Trek’s replicators to Richie Rich’s wishing machine, popular culture has a long history of parading flashy machines that can instantly output any item to a user’s delight. While 3D printers have now made it possible to produce a range of objects that include product models, jewelry, and novelty toys, we still lack the ability to fabricate more complex devices that are essentially ready-to-go right out of the printer.

.

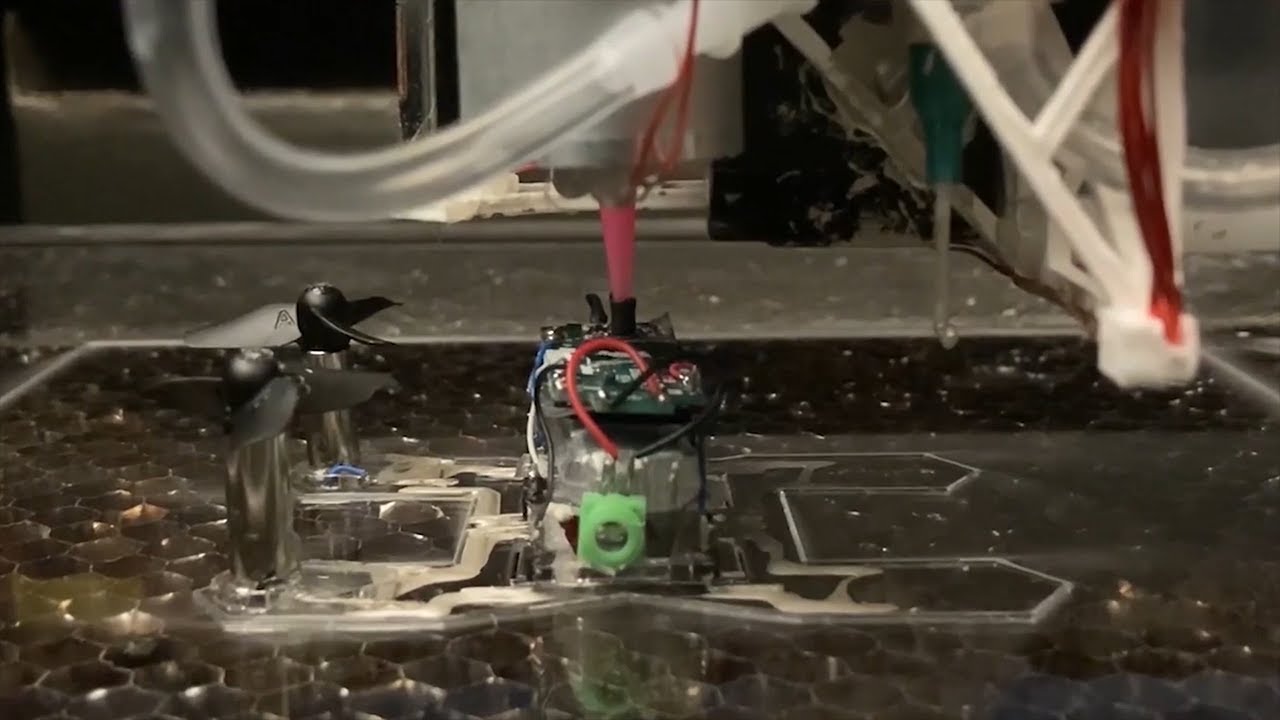

A group from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) recently developed a new system to print functional, custom-made devices and robots, without human intervention. Their single system uses a three-ingredient recipe that lets users create structural geometry, print traces, and assemble electronic components like sensors and actuators.

.

“LaserFactory” has two parts that work in harmony: a software toolkit that allows users to design custom devices, and a hardware platform that fabricates them. CSAIL PhD student Martin Nisser says that this type of “one-stop shop” could be beneficial for product developers, makers, researchers, and educators looking to rapidly prototype things like wearables, robots, and printed electronics. “Making fabrication inexpensive, fast, and accessible to a layman remains a challenge,” says Nisser, lead […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments