German researchers explore creep properties in superalloys, detailing their findings in the recently published ‘ Creep properties of single crystal Ni-base superalloys (SX): A comparison between conventionally cast and additive manufactured CMSX-4 materials .’

The authors compare both microstructures and the creep properties of two different types of single crystal Ni-base superalloys. Single crystal Ni-base superalloys (SXs) are extremely relevant to applications today like aerospace, energy, and more; for example, these metals can be used to create turbine blades—but they must be able to handle mechanical loads in extreme temperatures, over 1000 °C—and operate within the creep regime.

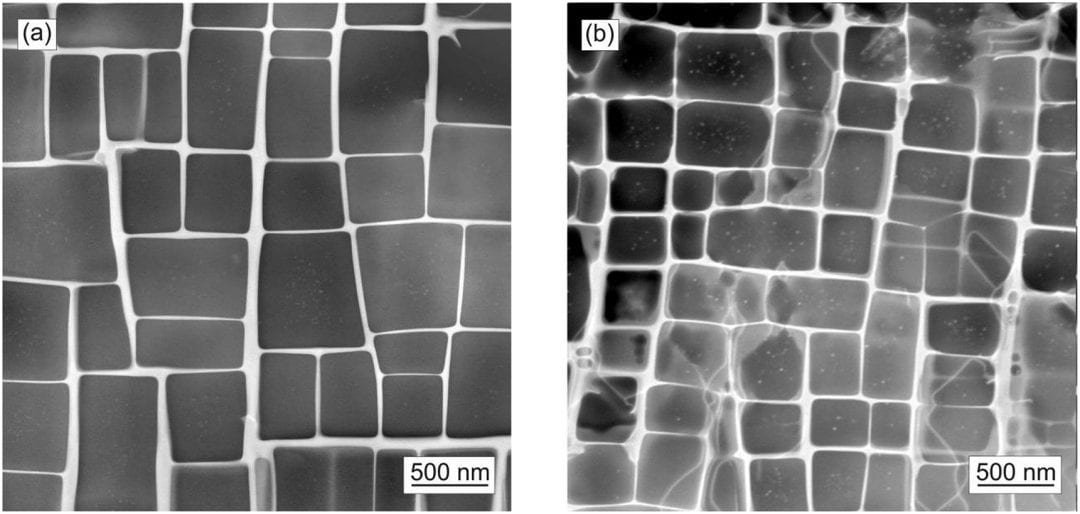

CMSX-4 materials possess what the researchers refer to as good creep strength because they are composed of refractory elements (W, Ta, Re). TEM micrographs of γ/γ′-microstructure taken from the materials investigated in the present work. (a) Fully heat treated cast SX. (b) Heat treated SEBM SX material. The particles were identified […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments