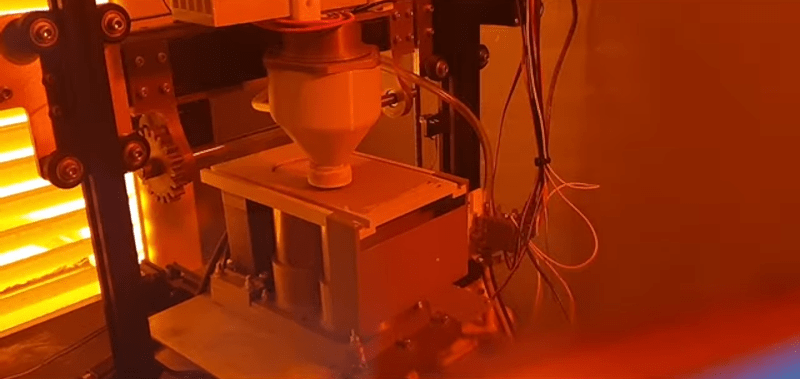

Most of our 3D printers lay down molten plastic or use photosensitive resin. But professional printers often use metal powder, laying out a pattern and then sintering it with a laser. [Metal Matters] is trying to homebrew a similar system (video, embedded below). And while not entirely successful, the handful of detailed progress videos are interesting to watch.

.

We particularly enjoyed the latest installment (the second video, below) which showed solutions to some of the problems.

.

.

Because of the complexity of the system, there are small tidbits of interest even if you don’t want to build a metal printer. For example, in the most recent video, a CCD camera gives up its sensor to detect the laser’s focus. Before you get the idea to try this with your cheap Chinese laser cutter, you should know that you’re going to have to splash out for some more lasers — the NUBM31 laser array from a laser projector has 20 diodes, each producing about 4.75 watts output. Not that we haven’t seen laser cutters used as 3D printers, though. We hear a 5 W laser is good enough to work with nylon . We realize [Metal Matters] has some work […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments