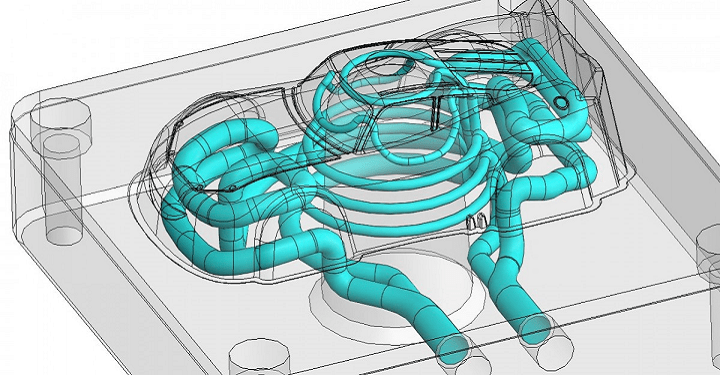

For over a decade, conformal cooling for molds has been an oft-cited 3D printing application. Conformal batteries are talked about periodically, as well. Sometimes you’ll see a mention of conformal antenna or things like heat sinks . So, what does conformal mean? And what effects will it have on design and manufacturing?

.

Essentially as outlined here in my article on flow , I’ll sum up the Flow Thesis as it stands right now. We can redesign almost anything not as a blocky mess of parts but as an optimized holistic shape that maximizes the flow of energy through that component. If you build on this by making a discrete geometry that is better at performing these flow tasks than other geometries, then, you can make a material for one particular part and application that is higher performing. This component, or flow geometry, material can then have a reduced mass, improved performance, and lower weight, all while reducing assembly steps and part count, as well as the buy-to-fly ratio. If we then make this geometry conformal or indeed a true flow geometry, it will not be a blocky solid mess of Lego bricks that need to be assembled, but rather […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments