Additive manufacturing, also known as 3D printing, is an invaluable platform for fabricating complex structures that would otherwise be time-consuming, or even impossible, to make using conventional techniques.

.

The ultimate goal is to fully control the composition, geometry and properties of 3D-printed structures at a microscopic level. However, for objects made from multiple materials, the minimum size of features that can be printed is limited, because the rate at which printers can switch between materials is too slow.

.

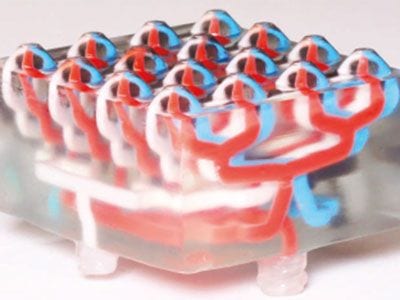

New technology is therefore needed to print fully functional, multi-material devices using a single printer. Writing in Nature , Skylar-Scott et al . 1 report a micrometre-scale printing strategy that enables fast switching between viscous materials extruded through a single nozzle.

.

The authors show that they can reduce the total printing time of certain structures by arranging up to 128 nozzles in parallel — a game changer for the field. Read […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments