Researchers from Canada and China have created a new technique for improving 3D printing, outlined in the recently published ‘ Topology Optimization for Multipatch Fused Deposition Modeling 3D Printing .’

.

The authors point out that as digital fabrication progresses further, new design rules are emerging, as well as constraints. These are related to supports and post-processing, size limitations, directional material properties, cellular structure, topology design, and more. Constrictions caused by anisotropic properties of AM materials motivated the researchers to create a hybrid topology optimization method for this study.

.

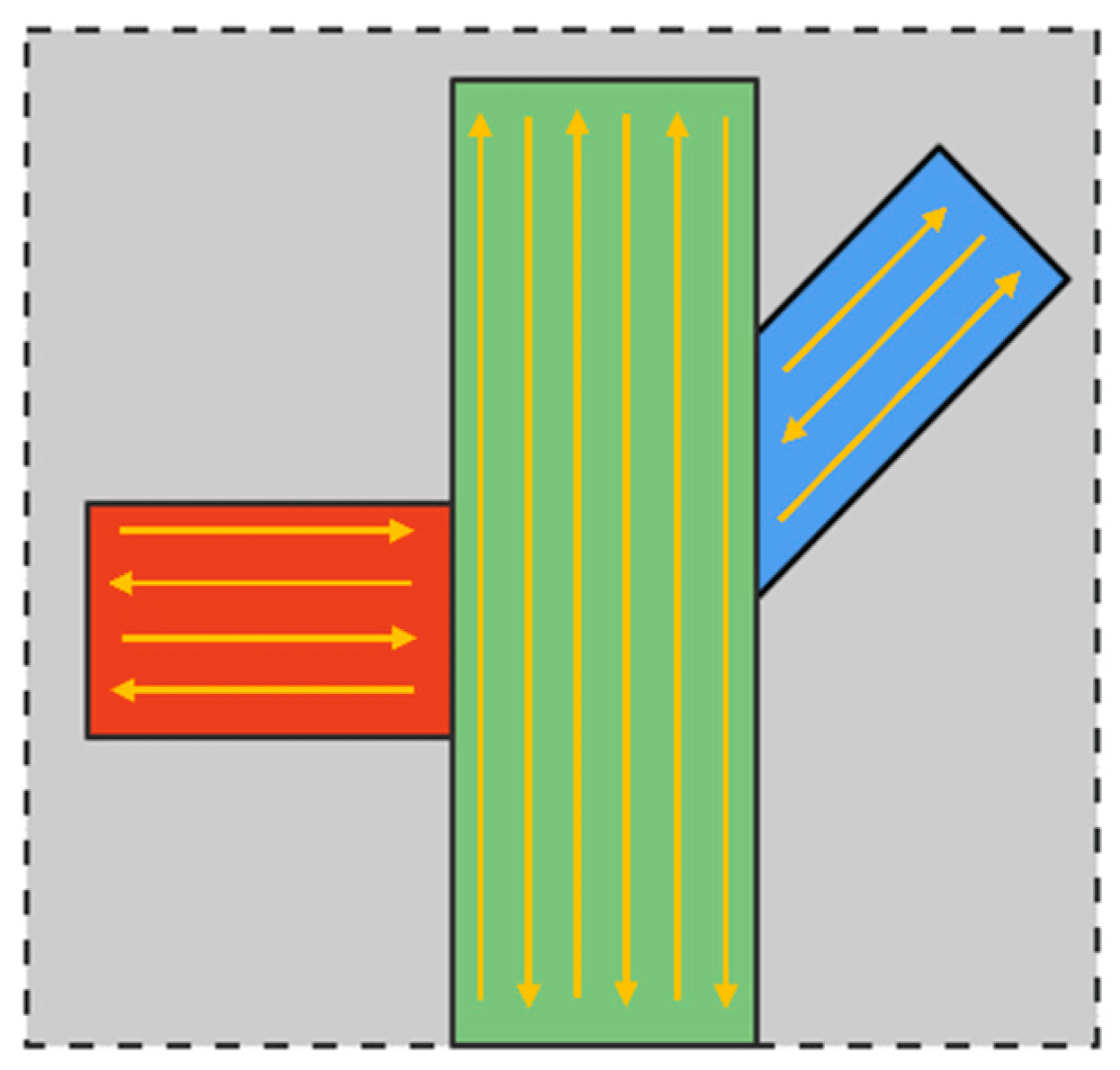

As directional material properties are related to the layering process, variations must be considered. With topology optimization, they can be handled, along with improving performance in printing through optimizing filament paths. The new technique proposed in this study ‘evolves from the traditional material/void interface design to a more sophisticated problem involving multiple levels of design freedom.’ These levels include the design […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments