Introducing complex geometric structures to fuel elements can enhance power output, safety margins, and accident tolerance. However, conventional techniques such as die pressing are not capable of fabricating fuel of irregular shapes.

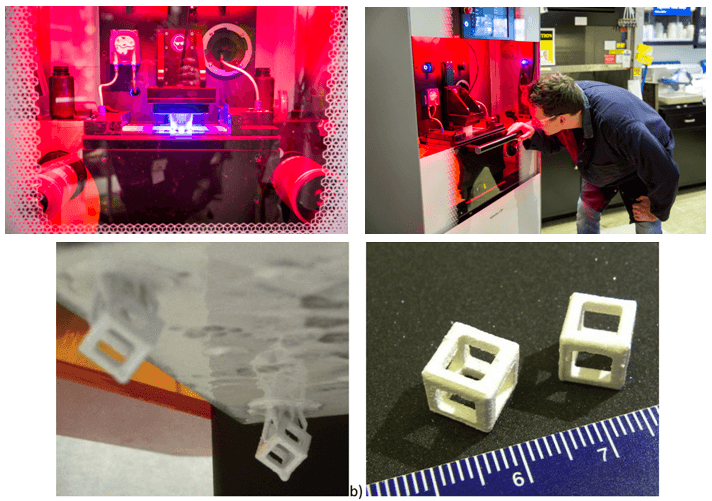

Last year, in a publication with the Journal of Nuclear Materials scientists at Canadian Nuclear Laboratories (CNL) reported they successfully generated high-density, thorium dioxide mock fuel parts, using a stereolithography-based 3D printer. “This is the very first attempt in the whole world to create nuclear fuel using 3D printing, the most cutting edge fabricating technology,” said Fuel Development scientist Andrew Bergeron in the interview with LabRoots. “The success we had with the printed thorium dioxide parts showed great potential for this brand new fuel […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments