3D printing is often touted as the future of manufacturing. It allows us to directly build objects from computer-generated designs, meaning industry can manufacture customized products in-house, without outsourcing parts.

.

But 3D printing has a high degree of error, such as shape distortion. Each printer is different, and the printed material can shrink and expand in unexpected ways. Manufacturers often need to try many iterations of a print before they get it right.

.

What happens to the unusable print jobs? They must be discarded, presenting a significant environmental and financial cost to industry.

.

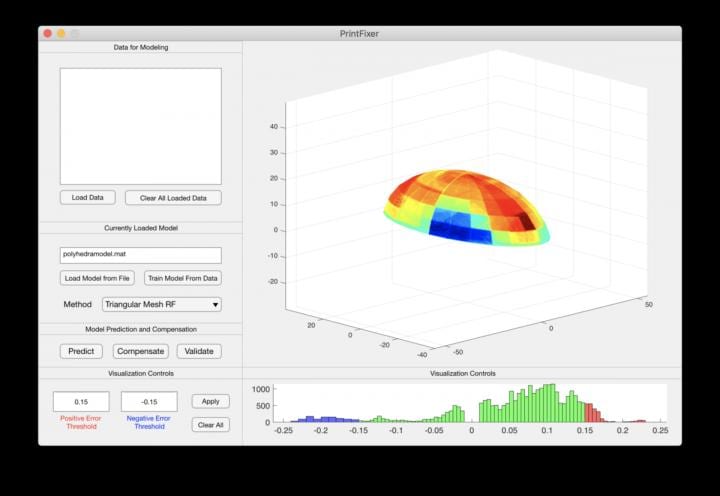

A team of researchers from USC Viterbi School of Engineering is tackling this problem, with a new set of machine learning algorithms and a software tool called PrintFixer, to improve 3-D printing […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments