Prashanth Ravi brings additional data to light in a recently published study, ‘ Understanding the relationship between slicing and measured fill density in material extrusion 3D printing towards precision porosity constructs for biomedical and pharmaceutical applications .’

.

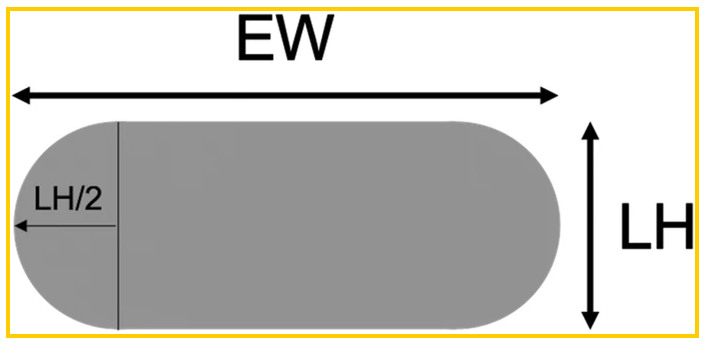

Helping us to understand more about the effects of slicing and porosity in biomedical applications, Ravi explores basic yet crucial printing parameters like fill density in FDM (FFF, Material Extrusion). While such topics have been the center of numerous research studies from use with 3D printed medical models, to materials like PLA , and new techniques and settings, in this study Ravi investigated discrepancies and deviations regarding the measured and slicing fill density for smaller-sized prints with low fill and high porosity. Schematic showing the cross-sectional shape of an extruded bead assumed by Slic3r. The EW and LH can be set in the software prior to slicing to adjust the […]

Materialise Introduces 100% Reused Powder with New 3-D Printing Service

Materialise Manufacturing, a leader in 3-D printing solutions with U.S. operations based in Plymouth Township, has...

0 Comments