A materials science and engineering team from Korea’s Yonsei University has developed a 3D printing technique enabling OLED screens to be printed into transparent structures of any shape, meaning nearly anything can become a see-through color display.

.

Published in the open access Advanced Science journal, the team aimed to take the development and manufacturing of complex screen shapes to the next level by printing both a 3D support structure and the 3D screen electronics.

.

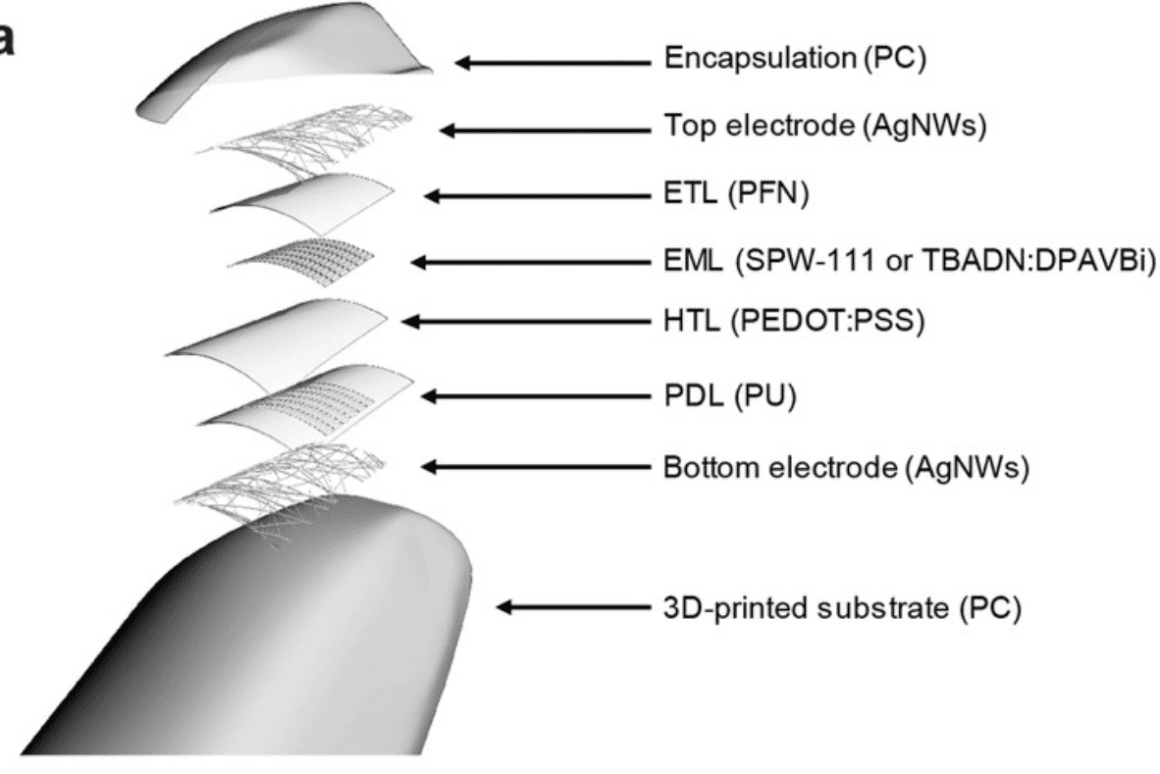

Current technology would generally require 3D structures to be fitted with linked 2D screens, whereas this technique enables designers to create screens of virtually any shape, without requiring any extra thermal annealing steps. The method uses a Digital Light Processing (DLP) system to print the transparent plastic “frames,” with gaps where the screens are to sit, and then moves to a five-axis electrohydrodynamic jet (e-jet) printer which can build up an OLED screen using the […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments