More durable prosthetics and medical devices for patients and stronger parts for airplanes and automobiles are just some of the products that could be created through a new 3D printing technology invented by a University of Massachusetts (UMass) Lowell researcher.

.

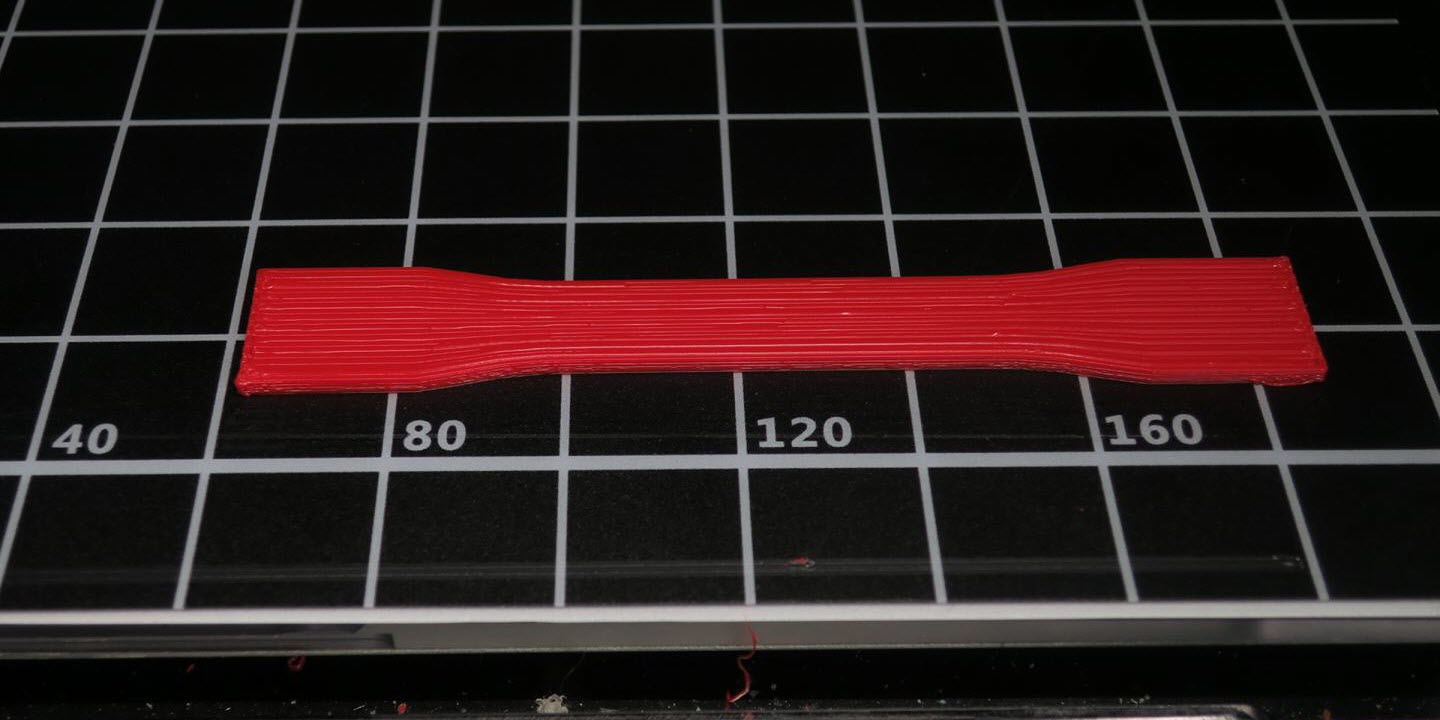

Substances such as plastics, metals and wax are used in 3D printers to make products and parts for larger items, as the practice has disrupted the prototyping and manufacturing fields. Products created through the 3D printing of plastics include everything from toys to drones. While the global market for 3D plastics printers is estimated at $4 billion and growing, challenges remain in ensuring the printers create objects that are produced quickly, retain their strength and accurately reflect the shape desired, according to UMass Lowell’s David […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments