Protect3d co-founders Kevin Gehsmann, Clark Bulleit and Tim Skapek began making customized 3D printed protective devices while they were still undergraduate engineering students at Duke University.

.

“It began as a series of projects using the skills we learned in our engineering classes and our experience as college football players to help our teammates,” said Skapek. In the fall of 2018, Gehsmann, Bulleit and Skapek watched teammate Daniel Jones break his collarbone during a game. Using 3D scanning and printing, they created an anatomically fitting brace to act as a bridge over Jones’ collarbone. Jones returned to play three weeks after the injury and he’s now quarterback for the New York Giants. Gregory Payan/AP Images for NFL The Protect3d co-founders pose with Daniel Jones (second to the left) backstage at the 2020 1st and Future event in Miami, Florida at Super Bowl LIV. (AP Images for NFL) “We got really positive feedback and we realized we could leverage cool innovations in 3D scanning to print a totally custom engineering grade product in a matter of hours.” Protect3d was born – and, after a few months of piloting their technology, the team applied to participate in 1st and Future , the […]

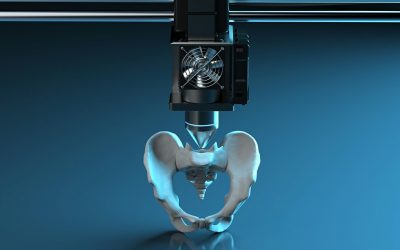

New treatment that uses 3D printed implants could bring relief to knee osteoarthritis sufferers

Pioneering 'printed metal' procedure to create bespoke treatment for early knee osteoarthritis set to be trialled in...

0 Comments