3D Printing in the Automotive Industry

8

JANUARY, 2021

Sammy Ekaran

3D printing has had a great impact on the automotive industry. Ranging from fast prototyping, production of finer parts of cars to even manufacturing of complete vehicles, the automotive industry is one of the sectors that has seen the potential of additive manufacturing and incorporated it in their production. 2020 has been a year of its own as many automotive companies saw the potential in the 3D printing technology and integrated it into their production processes.

Having entered into the new year 2021, it’s worth reflecting and seeing what was achieved in 2020. Let’s have a look at it!

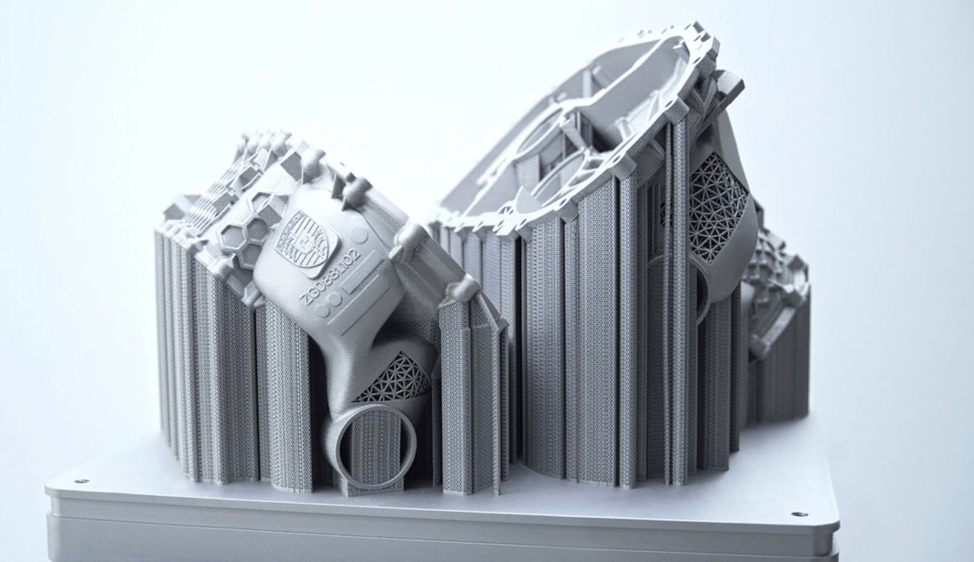

#1 BMW Opens an Additive Manufacturing Center

BMW has been researching and using in the field of 3D printing since 1990. They have been using this technology to produce high-quality and durable parts, which became the standard for prototypes, even for exclusive models.

A good example is the top cover of their i8 Roadster that was 3D printed. Achieving this using the traditional methods is hard, and the 3D printed parts also have less weight and are strong.

In June 2020, BMW opened its own 3D printing center with the goal of maximizing productivity. This campus has more than 50 industrial solutions with more than 80 employees. Their 3D printed parts are much lighter and stronger, which is why the i8 Roadster is mostly used in the sport.

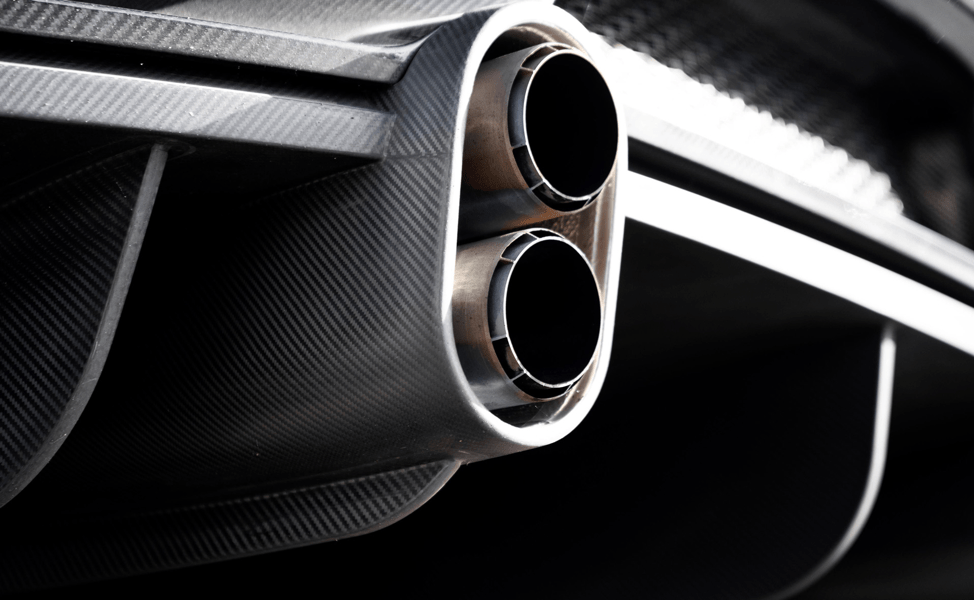

#2 Bugatti is using 3D printing to produce Heat Shields for their latest Hypercars

The exhaust system of Bugatti Chiron image source: Motorauthority

Bugatti is another one of the automotive companies using 3D printing to construct components for their cars. They first tested 3D printing by printing brake calipers and tested them before production. The results showed that the 3D printed brake functioned appropriately.

They are now expanding the use of additive manufacturing for their Hypercars. The company announced in October 2020 that they are now 3D printing heat shields used in the external exhaust systems. Each of the 3D printed components can be easily customized, which makes them unique.

The 3D printed heat shield is approximately 8.7 inches, 19 inches wide, and 5 inches high, and it weighs only 4.0 pounds, which is 2.0 pounds less than the one used when the traditional methods are used.

#3 Mustang Shelby GT500 Prints Parts For Hgh Performance

Ford company also adopted 3D printing in its early days. They opened their additive manufacturing center in order to integrate 3D printing in their product development.

They are using 3D printing in manufacturing their applications. The parts of their latest car in 2020, Shelby GT500 was 3D printed. Virtual design testing was first done to ensure it’s stability. More than 500 aerodynamic and cooling 3d designs were tested and analyzed to allow the team to reach its cooling, braking, and downfall targets. This car is one of the most advanced to date.

Once the promised design had been identified, the engineering team then went ahead to design and 3D print the prototypes. A good example is where the engineering team 3d printed and tested more than ten designs that were used for front splitter wickers.

The parking brake bracket of Ford.

Image credit: Ford

4. 3D printed Lamborghini goes for their first Spin

After the story of a 3D printed Lamborghini went viral in 2019, a lot has happened since then. Sterling Backus, who worked on the first 3D printed Lamborghini, has been continuously working on the project, and in July 2020, it was announced that he was taking it for a first spin.

Though this project is still work in process, what has been achieved so far is impressive, bearing in mind that everything was assembled in a garage.

5. Porsche Has Produced a 3D printed Housing for its electric drive

Electric drive housing. Image credit: Porsche

The 3D printed housing is lighter, more compact, and more rigid. The engine passed all the stress and quality tests without any problem. This shows 3D printing can be suitable for highly-stressed and large components for sports vehicles.

The engineers carried out several development steps with the prototype, which ensured that the final product had reduced weight by 10% when compared to the conventional cast part.

3D printing was the most preferred because the design was possible in every geometry when compared to other manufacturing methods. There is also extended design freedom as you can customize the designs as you want in 3D printing software before they are 3D printed.

6. Satair Produces 3D Printed Parts for Airbus

3d printed metal spare part bySatair image source: Airbus

An airbus services company, Satair provided one of their airlines with a certified 3d printed spare parts. The 3D printed parts were wingtips for fences for the A320ceo aircraft that weren’t procurable from original suppliers.

By using metal 3D printing technology, they were able to reduce the chances of the aircraft getting grounded. It also reduced the costs by almost 45% making it a cheaper solution for customers.