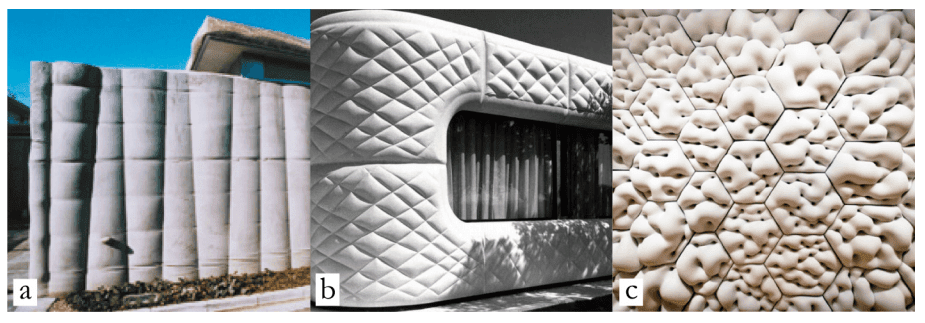

In the recently published ‘ Tailored flexibility: reinforcing concrete fabric formwork with 3D printed plastics ,’ authors Jon Engholt and Dave Pigram create a construction system integrating robotics and new techniques.

.

The study focused on concrete because of its flexibility, while pointing out that this material is still somewhat limited—thus explaining why flat forms are still so often used routinely while curved structures are avoided. Flexible materials offer great potential for improving the structure of buildings, however.

.

3D printing, accompanied by robotics capable of plastic extrusion, can outweigh some of the previous challenges often connected to fabric framework. This also includes benefits like added options for forms and surface qualities, with plastic working to reinforce material and performing as a design medium too. Concrete is usually cast in molds, and curves are typically considered hard to achieve, leaving users to turn to materials like timber; however, wood and milled […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments