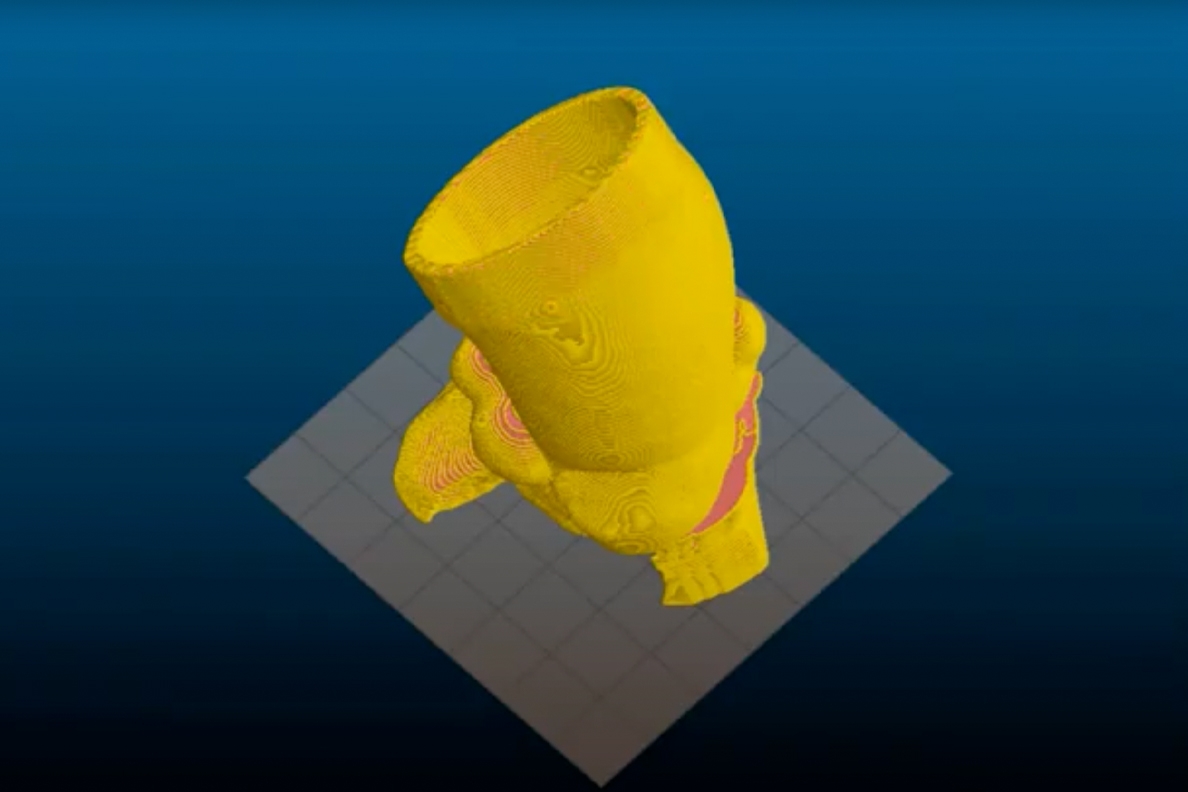

Researchers have developed a groundbreaking process for multi-material 3D printing of lifelike models of the heart’s aortic valve and the surrounding structures that mimic the exact look and feel of a real patient. These patient-specific organ models, which include 3D-printed soft sensor arrays integrated into the structure, are fabricated using specialized inks and a customized 3D printing process.

.

Such models can be used in preparation for minimally invasive procedures to improve outcomes in thousands of patients worldwide. Led by the University of Minnesota (UMN), with support from Medtronic, the research is published in Science Advances , a peer-reviewed scientific journal published by the American Association for the Advancement of Science (AAAS). Washington State University assistant professor Kaiyan Qiu, formerly a postdoctoral researcher at UMN, was one of the first authors of the work. The researchers 3D printed what is […]

Case Study: How PepsiCo achieved 96% cost savings on tooling with 3D Printing Technology

Above: PepsiCo food, snack, and beverage product line-up/Source: PepsiCo PepsiCo turned to tooling with 3D printing...

0 Comments