Researchers in New Zealand say they have developed a technique to 3D print ‘living’ and ‘self-repairing’ plastics.

.

The living’ resin is a 3D printable material which can change its properties after it has been produced, including growing in size and mass and repairing when damaged. Developed by researchers at the University of Auckland, it could be used in medical implants and the recycling of plastics.

.

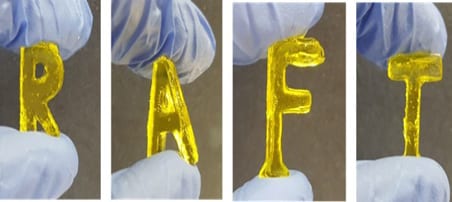

Self-repairing plastic offers the potential to reduce plastic waste, the cost and time to recycle which often means breaking down plastic objects into raw material for reuse. The team say the “world-first” 3D printing method uses a technique known as RAFT (reversible addition fragmentation chain transfer) polymerisation. The new technique advances 3D printing in two main ways with the big breakthrough being that the RAFT technique used produced objects that Dr Jin calls ‘dormant’.

.

Traditionally 3D printing produces inert objects that cannot change. RAFT objects can insert new compounds to alter their properties, enabling the printing of objects with the ability to transform after production. Additionally, traditional 3D printed objects are ‘cured’ or set with ultraviolet light. .

Click here to view original web page at www.manmonthly.com.au

0 Comments